Safety comes first when people replace crusher wear parts. Workers use the right tools and personal protective equipment. They follow manufacturer guidelines for Cone Crusher Parts, Jaw Crusher Jaw Plate Manganese Steel, and Bronze Parts. Teams check the Jaw crusher pitman before starting the job. Mistakes can lead to accidents.

Key Takeaways

- Always shut down and lock out the crusher before replacing wear parts to prevent accidents and ensure worker safety.

- Use the right tools, personal protective equipment, and follow step-by-step removal and installation procedures to protect both workers and equipment.

- Maintain clear communication and regular training among team members to improve safety, reduce downtime, and extend the life of crusher parts.

Preparation for Safe Crusher Wear Parts Replacement

Machine Shutdown and Isolation

Before anyone touches the crusher, they need to make sure the machine is completely off. Teams shut down the equipment and isolate it from any power source. This step keeps everyone safe from accidental start-ups. Workers gather all the tools and replacement parts they need. They also check the area for any damage that could cause problems later.

Tip: Always wear the right personal protective equipment (PPE) before starting. This includes hard hats, safety glasses, gloves, steel-toed boots, and high-visibility vests. Hearing protection is also important in noisy areas.

Lockout/Tagout Procedures

Lockout/tagout (LOTO) procedures protect workers from unexpected energy releases. Teams use locks and tags to secure switches and valves. They make sure no one can turn on the crusher by mistake. Each worker places their own lock and tag on the power source. This way, everyone knows who is working on the machine.

- LOTO steps usually include:

- Shut down the crusher.

- Isolate all energy sources.

- Lock and tag each source.

- Test to confirm the machine cannot start.

Clearing and Organizing the Workspace

A clean and organized workspace helps prevent accidents. Workers remove debris, tools, and leftover materials from the area. They set up proper lighting and make sure walkways are clear. Teams use proper lifting gear, like hoists or slings, for heavy Crusher wear parts. Good organization helps everyone work faster and safer.

Identifying Worn Crusher Wear Parts

Visual Inspection Techniques

Teams use visual inspection as the first step to spot problems with Crusher wear parts. They clean the parts with brushes, air compressors, or water jets. This helps them see cracks, chips, or uneven surfaces. Workers look for shiny spots, grooves, or missing chunks. They measure the depth and size of worn areas with calipers or gauges. Checking the fit and alignment of each part helps catch issues early. Regular cleaning and inspection make it easier to find trouble before it gets worse.

Tip: Keeping a detailed maintenance log helps teams track inspections and replacements. This record makes planning easier and helps spot patterns in wear.

Recognizing Signs of Wear and Damage

Workers look for common signs that show Crusher wear parts need attention. These signs include thinning metal, deep scratches, and broken edges. Sometimes, parts show uneven wear or strange noises during operation. Teams check for loose bolts or misaligned pieces. They also watch for vibration or changes in performance. The most common parts needing replacement include manganese steel jaw plates, chromium steel liners, and alloy steel components.

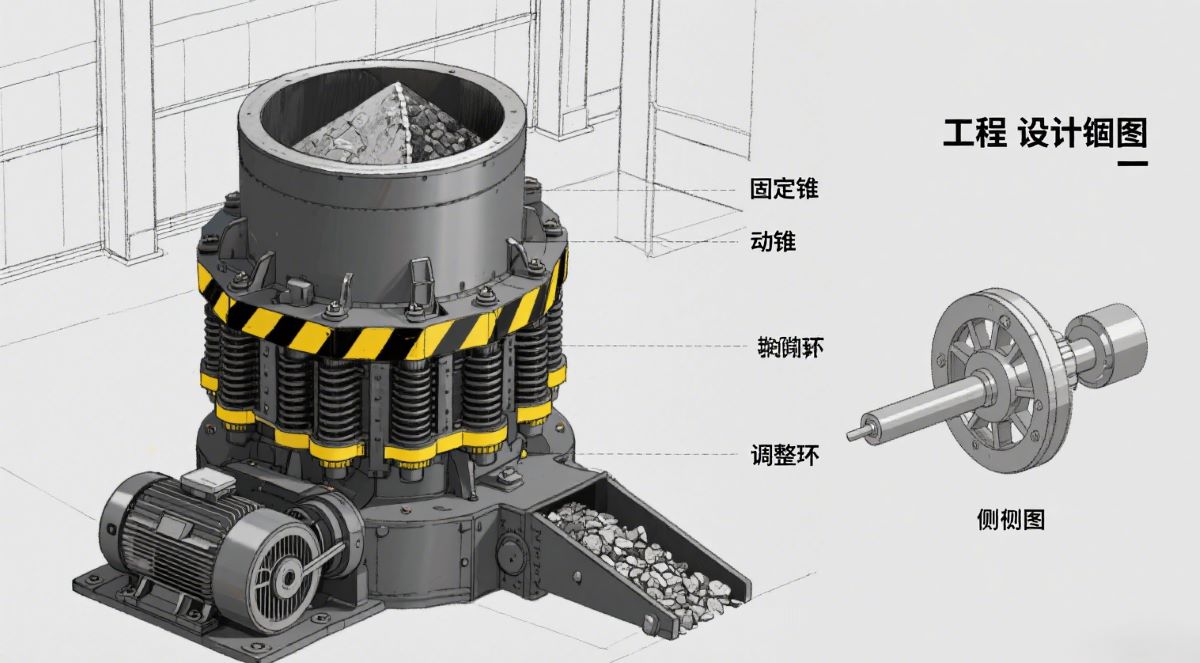

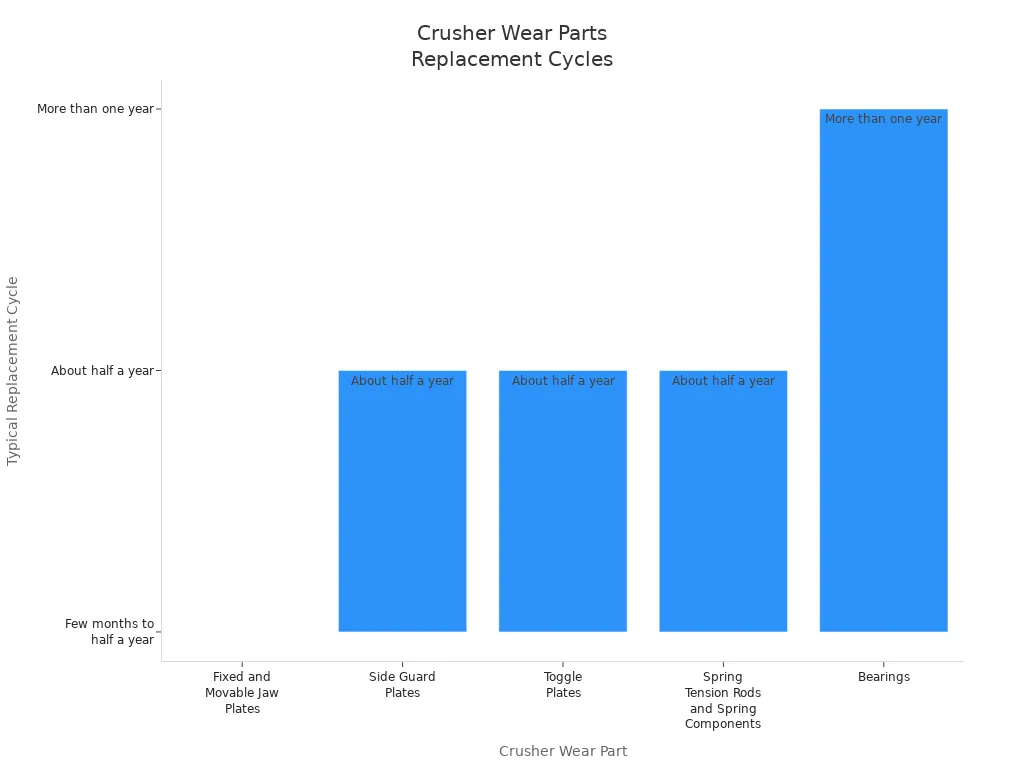

| Crusher Wear Part | Function / Role | Wear Characteristics and Cause | Typical Replacement Cycle |

|---|---|---|---|

| Fixed and Movable Jaw Plates | Main working components bearing huge impact loads during crushing | Serious wear especially in middle and lower parts due to repeated impact and friction | Few months to half a year depending on usage and material hardness |

| Side Guard Plates | Protect the crusher body from material impact | Wear from material impact | About half a year, varies with usage intensity |

| Toggle Plates | Connect movable and fixed jaw plates; act as insurance parts to prevent damage | Break under overload to protect crusher; sliding contact with little friction | About half a year |

| Spring Tension Rods and Spring Components | Connect adjustment seat and back support plate; maintain stability and absorb vibration | Buffer vibration and impact; wear or damage requires timely replacement | About half a year |

| Bearings | Bear radial loads during operation | Wear under long-term high load; require inspection and replacement | Generally more than one year |

Determining Replacement Timing

Teams work with equipment suppliers to understand wear patterns and set up maintenance schedules. They often replace mantle and cone liners at the same time to keep parts matched and reduce the risk of failure. Monitoring wear rates and planning replacements helps maximize part life and minimize downtime. Regular inspections, cleaning, and preventive maintenance—like lubrication and alignment checks—keep crushers running safely. Frequent checks help teams catch problems early and avoid costly repairs.

Safe Removal and Installation of Crusher Wear Parts

Using the Right Tools and Equipment

Choosing the right tools makes a big difference in safety and efficiency. Teams use wrenches, torque wrenches, and alignment tools to remove and install Crusher wear parts. Lifting devices like cranes or hoists help move heavy jaw plates without risking injury. Many sites now use special lifting systems such as LockLift™ and Safe-T Lift™. These systems follow strict Australian standards and help workers avoid welding lifting lugs, which can be dangerous. LockLift™ uses a patented torch ring, making the process faster and safer. Safe-T Lift™ lets workers remove liners without entering the crushing chamber, which keeps everyone out of harm’s way.

Tip: Always check tools and personal protective equipment before starting. Hard hats, safety goggles, gloves, steel-toed boots, and dust masks protect against falling debris and dust.

Step-by-Step Removal Process

A clear removal process keeps everyone safe and prevents damage to the equipment. Leading manufacturers recommend these steps:

- Disconnect the power and apply lockout/tagout devices. This stops the crusher from starting by accident.

- Try to start the machine to make sure it is off and all moving parts have stopped.

- Remove safety covers or panels with the right tools.

- Loosen bolts in a crisscross pattern. This prevents stress on the parts.

- Use lifting equipment to carefully remove old liners or jaw plates.

- Inspect the removed parts for cracks or damage. Write down anything unusual.

- Clean the mounting surfaces to remove rust, grease, or debris.

Following these steps helps teams avoid mistakes and keeps the Crusher wear parts in good shape for the next installation.

Installing New Wear Parts Safely

Proper installation matters just as much as safe removal. Teams line up new Crusher wear parts using alignment tools. They tighten bolts to the manufacturer’s recommended torque. This prevents misalignment, which can cause uneven wear or even equipment failure. Using the right materials and following instructions helps avoid overheating, vibration, and blockages. Teams also check for proper lubrication and make sure all sensors and control systems work. Skipping these steps can lead to higher maintenance costs and more downtime.

Note: Misaligned or poorly installed parts wear out faster and can damage the crusher. Always double-check alignment and bolt tightness.

Team Coordination and Communication

Good teamwork keeps the job safe and efficient. Shutdown optimization programs show that planning, training, and clear communication help teams finish faster and with fewer mistakes. Each person knows their role, and everyone follows the same safety steps. Teams remove non-critical tasks and focus on what matters most. In some mines, better coordination has cut shutdown times almost in half. Regular inspections and maintenance schedules only work when everyone stays in sync. Operators, maintenance workers, and experts must work together to replace Crusher wear parts safely and on time.

When everyone communicates and works as a team, the risk of accidents drops and the crusher runs better.

Post-Replacement Checks for Crusher Wear Parts

Testing and Initial Operation

After installing new Crusher wear parts, the team should start with a careful test run. They keep the crusher stopped and locked out while checking the weight of each part and making sure the lifting equipment can handle it. Workers use special tools to secure the parts and inspect lifting holes on cheek plates. When the crusher starts, they listen for strange noises and watch for any shaking. They check the product size and quality. If something seems off, they stop the machine and look for problems. Teams also check the lubrication system to make sure oil levels and pressure are right. This first test helps catch issues before they become bigger problems.

Final Inspection and Adjustments

A final inspection makes sure everything works as it should. Workers look at all critical parts, such as rotors, liners, bearings, and cheek plates. They search for signs of damage or wear. The team checks if bolts and fasteners are tight and if the parts fit together well. They also look for changes in energy use or blockages. If they find anything wrong, they make quick adjustments. Regular inspections and having spare parts ready help keep the crusher running smoothly.

Tip: Rotate jaw dies after 50-200 hours, then every 400-500 hours, to extend their life and keep performance high.

Documentation and Record Keeping

Good records help teams track the health of Crusher wear parts. Workers take monthly photos to watch for wear patterns. They write down details like the crusher’s make, model, serial number, and location. They also record inspection dates, who did the work, and how many hours the crusher has run since the last check. Teams use digital tools to store this information and compare it over time. These records help spot trends, plan future maintenance, and meet safety rules.

Training and Maintenance for Crusher Wear Parts

Importance of Regular Training

Regular training keeps everyone safe and confident when working with Crusher wear parts. A strong training program covers many topics:

- Teams learn how to feed material into crushers the right way to avoid overloads.

- Everyone must use personal protective equipment like hard hats, safety glasses, and dust masks.

- Workers understand site safety rules, such as staying out of exclusion zones and following signs.

- Training includes daily inspections, wear part checks, and how to use lockout/tagout steps.

- Operators get to use new tools, like remote controls and automated shutdown systems.

- Ongoing learning and certification help workers keep up with new equipment and safety rules.

- Well-trained teams have fewer accidents and keep machines running longer.

Proper training also teaches the right way to handle and install parts, which helps prevent damage and keeps everyone safe.

Scheduled Maintenance Practices

Scheduled maintenance helps Crusher wear parts last longer and keeps the crusher running smoothly. Teams follow a plan that includes:

- Inspecting wear patterns and checking for cracks or loose bolts.

- Lubricating bearings and checking liners every week or month.

- Using special tools to measure wear and spot problems early.

- Adjusting crusher settings and making sure the feed is even.

- Installing parts correctly and checking alignment.

- Training everyone on safe operation and wear recognition.

- Using quality parts from trusted suppliers.

- Keeping extra parts in stock and tracking them with software.

A good maintenance schedule also includes cleaning, vibration checks, and protecting parts from dust and moisture.

Continuous Improvement and Safety Culture

Continuous improvement means always looking for better ways to work. Teams use new tools and safer procedures to replace parts faster and with less risk. They choose materials that reduce noise and vibration, making the job safer. Regular monitoring helps teams replace worn parts before they cause trouble. A strong safety culture brings real benefits:

- Fewer accidents and breakdowns

- Lower maintenance costs

- Less downtime

- Better employee morale

Every dollar spent on preventive maintenance can save up to ten dollars in repairs. A safe workplace helps everyone do their best work.

Safety matters at every step when replacing Crusher wear parts. Teams prepare, inspect, and follow safe procedures. They check parts after installation and keep learning new skills. Strictly following manufacturer guidelines helps prevent accidents and keeps equipment running longer.

Good habits save money and protect workers.

- Prepare before starting

- Inspect parts often

- Use safe removal and installation steps

- Check everything after replacement

- Train teams regularly

FAQ

How often should teams inspect crusher wear parts?

Teams check wear parts every week. Regular inspections help spot damage early and keep the crusher running safely.

What personal protective equipment does everyone need?

Workers wear hard hats, safety glasses, gloves, steel-toed boots, and high-visibility vests. Hearing protection helps in loud areas.

Can someone reuse old crusher wear parts?

No, teams should not reuse worn parts. Old parts break easily and cause safety risks. Always use new, manufacturer-approved replacements.

Post time: Aug-13-2025