High manganese steel stands out due to its unmatched wear resistance and toughness, making it an essential component in the Parts Of Crusher Machine. This material can endure extreme conditions, which enhances operational efficiency in the mining sector. Notably, companies save significantly with high manganese steel, particularly when utilizing Manganese Steel Hammer in their operations. For instance, they can achieve annual savings of $3.2 million across various cost categories. This includes $1.95 million saved from reduced unplanned downtime, improving equipment availability from 76.5% to 91.2%. Additionally, emergency repair costs drop by $680,000 annually due to early problem detection and planned maintenance, especially when employing Manganese Wear Plate for added durability. Furthermore, effective Machining Manganese Steel allows for precise fabrication of components, further enhancing the performance and longevity of machinery in demanding environments.

Key Takeaways

- High manganese steel offers unmatched wear resistance and toughness, making it essential for mining equipment.

- Using high manganese steel can save companies up to $3.2 million annually by reducing downtime and repair costs.

- The work hardening ability of high manganese steel increases its hardness under impact, enhancing its durability in harsh conditions.

- High manganese steel components can last significantly longer than alternatives, leading to lower maintenance and replacement costs.

- Investing in high manganese steel improves operational efficiency, reducing downtime by up to 30% and enhancing productivity.

Unique Properties of High Manganese Steel

Composition and Structure

High manganese steel, often referred to as Hadfield steel, contains a unique blend of elements that contribute to its exceptional properties. The typical chemical composition of high manganese steel used in mining crushing applications includes:

| Grade | C (%) | Mn (%) | P (%) | S (%) | Cr (%) | Ni (%) |

|---|---|---|---|---|---|---|

| GX120Mn13 | 1.05-1.15 | 11-14 | Max. 0.06 | Max. 0.045 | – | – |

| GX120MnCr13-2 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | 1.5-2.5 | – |

| GX120Mn18 | 1.05-1.35 | 16-19 | Max. 0.06 | Max. 0.045 | – | – |

| GX120MnCr18-2 | 1.05-1.35 | 16-19 | Max. 0.06 | Max. 0.045 | 1.5-2.5 | – |

| GX120MnNi13-3 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | – | 3-4 |

| GX120MnMo13-2 | 1.05-1.35 | 11-14 | Max. 0.06 | Max. 0.045 | – | 1.8-2.1 |

The primary components of high manganese steel include manganese, carbon, and iron. Manganese content typically ranges from 11% to 14%, while carbon varies by grade. This specific composition results in a microstructure that enhances wear resistance and toughness.

The microstructure of high manganese steel plays a crucial role in its performance. It features a heterogeneous structure with fine-grained pearlite and carbides. This arrangement increases abrasion resistance by approximately 16.4%. The material also exhibits high toughness and ductility, making it suitable for applications that require resistance to impact and abrasive wear.

Work Hardening Characteristics

One of the standout features of high manganese steel is its remarkable work hardening ability. When subjected to impact, the material undergoes a transformation that significantly increases its hardness. This phenomenon occurs due to the formation of ε-martensite and mechanical twins within the steel matrix.

The following table illustrates the hardness increase observed in different grades of high manganese steel under impact conditions:

| Material | Matrix Hardness (HV) | Worn Sub-surface Hardness (HV) | Hardness Increase (HV) | Mechanism of Hardening |

|---|---|---|---|---|

| Mn13 | 240.2 | 670.1 | 429.9 | Formation of ε-martensite and mechanical twins |

| Mn13-2 | 256.6 | 638.2 | 381.6 | Formation of ε-martensite and mechanical twins |

| Mn18-2 | 266.5 | 713.1 | 446.6 | Formation of ε-martensite and mechanical twins |

This work hardening characteristic allows high manganese steel to absorb significant energy during operation. As a result, it can withstand high-impact loads without fracturing. This property makes it particularly valuable in mining applications, where equipment faces extreme conditions.

In comparison to other commonly used mining materials, high manganese steel exhibits superior work hardening capabilities. While it may show low yield strength under moderate or low-impact loading, its performance under high-impact conditions is unmatched. This unique combination of properties ensures that high manganese steel remains a preferred choice in the mining industry.

Advantages of High Manganese Steel Over Alternative Materials

High manganese steel offers significant advantages over alternative materials in mining crushing applications. Its unique properties contribute to enhanced durability and cost-effectiveness, making it a preferred choice for many mining operations.

Durability and Longevity

Durability is a critical factor in mining equipment. High manganese steel components typically exhibit a longer service life than other materials, especially under normal operating conditions. For instance, high manganese steel grades, such as Mn22, demonstrate exceptional wear and impact resistance. These liners can last between 250 to 500 hours in abrasive conditions, significantly outlasting standard manganese steel.

In comparison, alloy steel components can last more than three times longer than high manganese steel under similar working conditions. Laboratory tests confirm that alloy steel jaw plates resist wear better, particularly in abrasive environments. The following table summarizes the durability characteristics of high manganese steel versus alloy steel:

| Property | High Manganese Steel | Alloy Steel |

|---|---|---|

| Wear Resistance | Tends to wear faster in certain conditions | Resists wear better, lasts longer |

| Impact Resistance | Good impact resistance | Moderate impact resistance |

| Hardness | Can work-harden but lower overall hardness | Higher hardness (HRC 48-51) |

| Durability | Generally less durable than alloy steel | Can last three times longer |

| Modification Potential | Can be modified with chromium/molybdenum | Not typically modified |

The work-hardening ability of high manganese steel allows it to absorb significant energy during operation. This property enhances its durability, making it suitable for high-impact applications in mining.

Cost-Effectiveness

Cost-effectiveness is another crucial advantage of high manganese steel. Although the initial investment may be higher than some alternatives, the long-term savings often outweigh these costs. High manganese steel components generally provide a significantly extended service life compared to alternative materials. This longevity translates into reduced replacement frequency and lower maintenance costs.

Moreover, the use of high manganese steel can lead to substantial savings in operational costs. Companies can minimize downtime and repair expenses, which contributes to overall efficiency. For example, high chrome alloy steel parts can last three to four times longer than standard manganese steel plates. This extended lifespan reduces the need for frequent replacements, ultimately leading to lower total costs.

Applications of High Manganese Steel in Mining Crushing

Crusher Liners

High manganese steel plays a vital role in the production of crusher liners. These liners are essential components in various high-wear industries, including quarrying, mining, excavation, and the coal sector. They withstand intense material friction and crushing impacts, ensuring stable operation of crushers. The superior wear resistance and extended service life of high manganese steel make it ideal for heavy-duty applications.

The following table highlights the performance improvements observed when using high manganese steel in crusher liners:

| Performance Improvement | Description |

|---|---|

| Excellent Wear Resistance | High-manganese steel liners exhibit exceptional wear resistance, extending equipment life. |

| Self-Hardening Properties | The liners increase in surface hardness over time, enhancing wear resistance and operational efficiency. |

| Enhanced Crusher Efficiency | Higher hardness leads to more effective crushing, reducing energy loss and improving production capacity. |

| Reduced Equipment Maintenance Frequency | Increased surface hardness results in slower wear, reducing the need for frequent replacements. |

| Improved Overall Production Efficiency | Longer service life and reduced downtime enhance production line continuity and overall productivity. |

| Strong Impact Resistance | The liners withstand intense impact, maintaining stable operation and reducing maintenance costs. |

| Reduced Operating Costs | Less frequent maintenance and replacements lower operating costs and improve economic benefits. |

Jaw and Cone Crushers

High manganese steel significantly enhances the performance of jaw and cone crushers. Approximately 70% of jaw and cone crushers in the mining industry utilize high manganese steel components. This material offers exceptional toughness and durability, crucial for absorbing shocks in high-pressure environments.

The unique properties of high manganese steel allow it to absorb and dissipate shock energy effectively. This prevents cracks or fractures, which is vital for processing hard materials. The following points summarize the benefits of high manganese steel in jaw and cone crushers:

- Manganese steel work-hardens with each impact, increasing its resistance to abrasion.

- It maintains high toughness, absorbing significant impact energy without cracking.

- This combination allows it to perform well in abrasive and high-impact conditions.

By reducing the need for frequent part replacements, high manganese steel minimizes downtime and enhances overall productivity. Its cost-effectiveness stems from the extended lifespan of components, which leads to lower maintenance needs.

Impact of High Manganese Steel on Efficiency and Productivity

Reduced Downtime

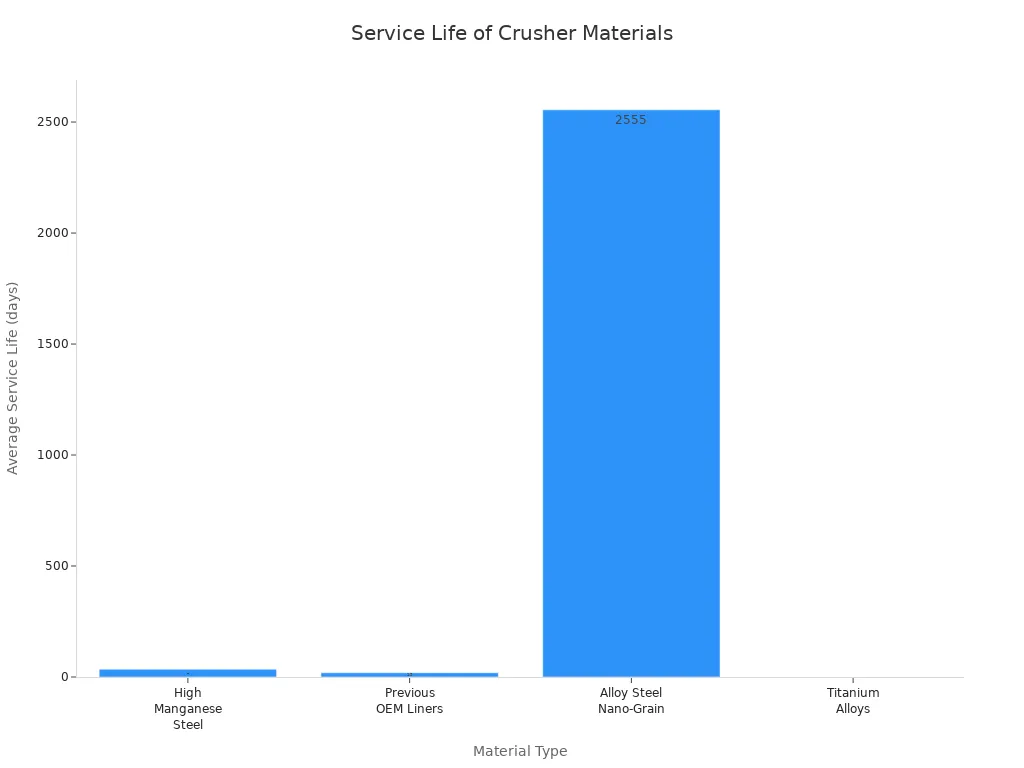

High manganese steel significantly reduces downtime in mining operations. Its durability and wear resistance lead to longer service life for components. For example, high manganese steel liners can last an average of 35 days, compared to only 19 days for previous OEM liners. This improvement allows mining companies to maintain continuous operations without frequent interruptions for part replacements.

| Material Type | Average Service Life | Notes |

|---|---|---|

| High Manganese Steel (Xtralloy) | 35 days | Significant improvement over previous OEM liners. |

| Previous OEM Liners | 19 days | Lower service life compared to Xtralloy. |

| Alloy Steel with Nano-Grain Forging | 5-7 years | Longer lifespan than high manganese steel. |

| Titanium Alloys | 7-9 years | Superior lifespan compared to high manganese steel. |

The extended lifespan of high manganese steel components leads to fewer maintenance shutdowns. Clients have reported reductions in maintenance downtime by up to 30% after switching to high manganese steel parts. This reduction not only enhances productivity but also contributes to significant cost savings.

Enhanced Performance Metrics

High manganese steel enhances several performance metrics in mining crushing equipment. Its unique properties improve wear resistance, toughness, and overall durability. As a result, mining operations experience:

- Wear Resistance: High manganese steel becomes harder over time when exposed to friction, making it ideal for applications where wear is a concern.

- Toughness: The material’s toughness enhances its ability to withstand impact and abrasive forces, crucial in mining environments.

- Durability: Overall durability is improved, leading to reduced downtime and lower maintenance costs.

The prediction model for the lifetime of crushing plates shows a low root mean square error (RMSE) of 0.0614 hours. This accuracy indicates that high manganese steel significantly enhances productivity, with lifetimes ranging from 746 to 6902 hours. Companies that focus on quality parts experience productivity improvements of up to 20%.

By investing in high manganese steel components, mining operations can achieve better performance metrics and operational efficiency.

High manganese steel‘s properties make it indispensable in mining crushing applications. Its unique composition enhances durability, wear resistance, and toughness. This material significantly improves productivity and cost savings for mining operations. Key benefits include:

- Extended maintenance intervals by 30–40%

- Reduced frequency of part replacements

- Lower operating costs

The demand for high manganese steel is projected to rise due to its unmatched performance in harsh conditions. As mining technologies evolve, the continued use of high manganese steel remains essential for efficient operations.

| Property/Function | Description |

|---|---|

| Deoxidising Agent | Removes oxygen and sulphur impurities from molten steel, improving strength and durability. |

| Alloy Strengthener | Enhances toughness, hardness, and wear resistance by forming stable compounds with carbon. |

| Hardenability Booster | Increases hardenability, making steel suitable for structural applications under stress. |

| High-Manganese Steel | Contains 12–14% manganese, known for exceptional work-hardening properties, ideal for mining. |

FAQ

What is high manganese steel?

High manganese steel is an alloy containing 11-14% manganese. It is known for its exceptional toughness and wear resistance, making it ideal for mining applications.

How does high manganese steel work harden?

High manganese steel work hardens when subjected to impact. This process increases its hardness, allowing it to absorb more energy and resist wear.

What are the main applications of high manganese steel in mining?

High manganese steel is primarily used in crusher liners, jaw crushers, and cone crushers. Its durability makes it suitable for high-impact and abrasive environments.

Why is high manganese steel cost-effective?

Although high manganese steel may have a higher initial cost, its long service life and reduced maintenance needs lead to significant savings over time.

How does high manganese steel compare to other materials?

High manganese steel offers superior wear resistance and toughness compared to other materials like alloy steel. This makes it a preferred choice for demanding mining applications.

Post time: Oct-24-2025