A cone crusher relies on high-grade materials to handle tough jobs, particularly its cone crusher components. Manganese steel, especially Hadfield steel, dominates its construction. This material offers remarkable toughness and wear resistance, with over 12% manganese that hardens during use. Cast iron and ceramic composites also enhance the durability of the cone crusher, ensuring it withstands immense pressure and abrasive conditions.

Key Takeaways

- Manganese steel is the main material in cone crushers. It is very strong and resists wearing out.

- Strong materials like ceramic mixes make parts last longer. They also help the cone crusher work better and need less fixing.

- Picking the right materials and adjusting settings can help a lot. It makes the crusher work well and last longer.

Cone Crusher Components and Their Materials

Mantle and Concaves

The mantle and concaves are critical cone crusher components that directly interact with the material being crushed. These parts are typically made from manganese steel, which hardens under pressure and resists wear. The mantle sits atop the main shaft, while the concaves form the stationary bowl around it. Together, they create the crushing chamber where rocks are compressed and broken down.

Performance reports show that wear rates for these components depend on factors like ore properties and operational metrics. High wear zones on the concave liners often appear in the mid and bottom rows, while the mantle experiences more evenly distributed wear. This highlights the importance of selecting durable materials and optimizing the crusher’s settings to extend the life of these components.

Main Shaft and Eccentric Bushing

The main shaft and eccentric bushing are the backbone of a cone crusher’s operation. The main shaft supports the mantle and transfers the crushing force, while the eccentric bushing allows the mantle to move in a gyratory motion. These components are usually crafted from high-strength steel and bronze alloys to endure the immense pressure and rotational forces involved.

- Common issues with the eccentric bushing include:

- Overheating of lubricating oil

- Bronze filings in the hydraulic unit screen

- Total lockup of the crusher

- Factors contributing to bushing burnout:

- Improper lubrication

- Faulty liners or incorrect configurations

- Excess fines in the feed material

When a burnout occurs, technicians must identify the root cause, clean and polish the main shaft, and measure the damaged parts for replacement. Proper maintenance ensures these cone crusher components perform efficiently and last longer.

Frame and Tramp Release Mechanism

The frame provides structural support for all cone crusher components. It is typically made from cast steel or iron to ensure stability and withstand heavy loads. The tramp release mechanism, on the other hand, protects the crusher from damage caused by uncrushable materials like metal debris.

This mechanism uses hydraulic systems to release pressure and allow the uncrushable material to pass through safely. Manufacturers often use ceramic composites and high-grade steel for these parts to ensure durability and reliability. A well-designed frame and tramp release mechanism contribute to the crusher’s overall efficiency and safety during operation.

Why These Materials Are Used

Durability and Wear Resistance

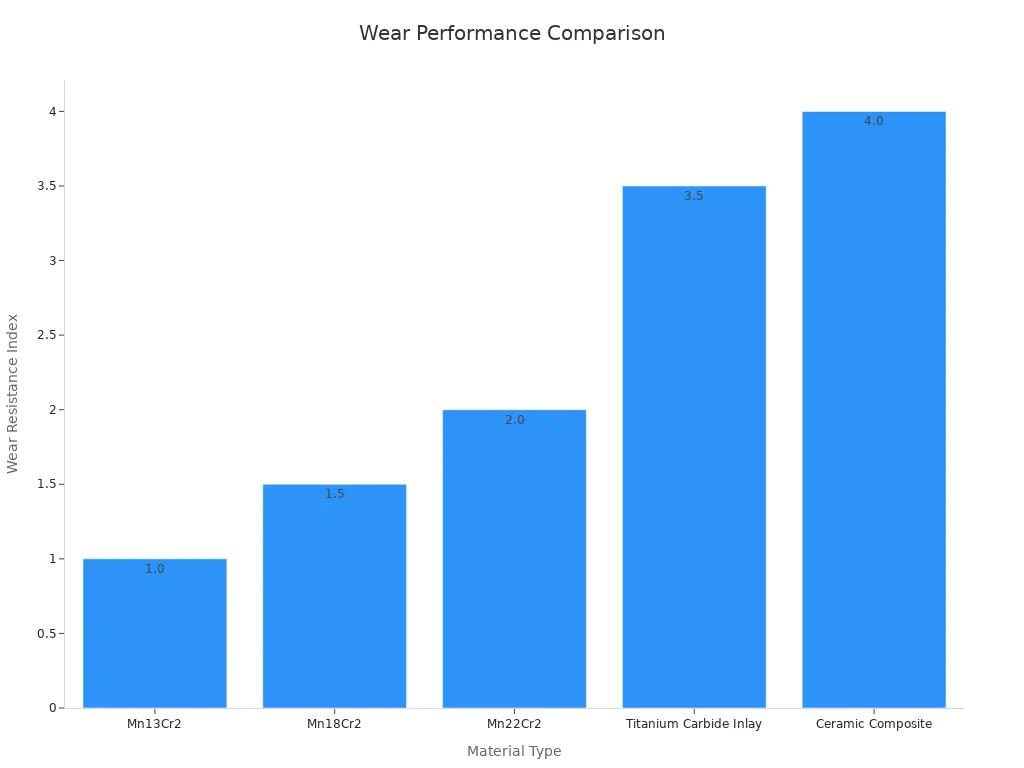

Cone crusher components face extreme wear and tear during operation. To combat this, manufacturers use materials like manganese steel and ceramic composites. Manganese steel, especially grades like Mn13Cr2 and Mn18Cr2, hardens under stress, making it ideal for crushing abrasive materials. Ceramic composites, on the other hand, offer ultra-high hardness and maintain their sharp crushing profile even in demanding conditions.

| Material Type | Hardness (HRC) | Wear Resistance Index | Impact Resistance | Expected Lifespan (hours) |

|---|---|---|---|---|

| Mn13Cr2 | 18-22 | 1.0 | ★★★★★ | 800-1200 |

| Mn18Cr2 | 22-25 | 1.5 | ★★★★☆ | 1200-1800 |

| Ceramic Composite | 60-65 | 4.0 | ★☆☆☆☆ | 3000-4000 |

These materials ensure the crusher can handle prolonged use without frequent replacements, reducing downtime and maintenance costs.

Strength for High-Pressure Applications

Cone crushers operate under immense pressure, especially when processing hard materials like quartz or granite. High-strength steel and titanium carbide inlays are commonly used for components like the main shaft and mantle. Titanium carbide inlays, for instance, improve wear resistance by 1.8 times and impact toughness by 8.8 times compared to traditional materials. This strength ensures the crusher can handle high-pressure applications without compromising performance.

Adaptability to Various Crushing Needs

Different crushing tasks require materials that can adapt to varying conditions. For example, Mn18Cr2 excels in handling irregular materials with impurities due to its excellent impact resistance. Ceramic composites are better suited for fine crushing of ultra-hard materials. Performance tests using numerical simulations, such as the discrete element method (DEM), have shown that optimizing parameters like rotational speed and cone angles can further enhance adaptability. A Y51 cone crusher, for instance, achieved peak productivity with a precession angle of 1.5° and a rotational speed of 450 rad/min.

By selecting the right materials and configurations, cone crusher components can meet diverse operational demands while maintaining efficiency.

How Materials Impact Crusher Performance

Enhanced Efficiency and Longevity

The materials used in cone crusher components play a huge role in improving efficiency and extending the machine’s lifespan. High-quality materials like manganese steel and ceramic composites ensure that parts can handle heavy-duty use without wearing out quickly. For example, wear-resistant materials can last two to four times longer than traditional ones, reducing the need for frequent replacements.

| Evidence | Description |

|---|---|

| High-quality materials | Used for manufacturing durable parts. |

| Wear-resistant materials | Improve durability, lasting 2 to 4 times longer. |

Durable materials also reduce energy loss during operation. Studies have shown that crushers built with robust materials experience less wear and tear, which means they maintain their performance over time. This durability ensures that the crusher operates efficiently, even under tough conditions.

| Evidence | Description |

|---|---|

| High-quality cone crushers | Engineered to last with abrasion-resistant materials. |

| Robust materials | Lead to less wear and tear, improving efficiency. |

Reduced Maintenance and Downtime

Frequent maintenance can disrupt operations and increase costs. By using strong and wear-resistant materials, manufacturers minimize the need for repairs. For instance, manganese steel hardens under stress, making it ideal for parts like the mantle and concaves. This property reduces the wear rate, allowing the crusher to run longer without interruptions.

A large-scale study in 1982 measured the breakage energy and ore fracture characteristics of production crushers. The results showed that using high-quality materials significantly reduced operational disturbances. Specimens from the study were tested with high-energy pendulum procedures, confirming the materials’ ability to withstand extreme conditions.

Additionally, material selection impacts how well the crusher handles different cavity levels. Crushers operating with full cavities and hard rock materials show enhanced production efficiency. On the other hand, low-cavity operations with soft rock materials often lead to variable performance, requiring more frequent adjustments.

| Cavity Level | Material Type | Observed Effects |

|---|---|---|

| Low cavity | Soft rock | Increased power utilization. |

| High cavity | Hard rock | Improved reduction properties. |

Improved Crushing Precision

The right materials also enhance the precision of the crushing process. For example, ceramic composites maintain their sharp crushing profile, even after prolonged use. This consistency ensures that the crusher produces uniform-sized materials, which is crucial for industries like construction and mining.

Automatic size reduction control systems further improve precision. Crushers equipped with these systems experience 38-46% less variation in performance metrics. Consistent production also boosts average circuit performance by 12-16%, making the crusher more reliable.

| Key Findings | Impact on Performance |

|---|---|

| Automatic size reduction control | 38-46% lower variation in performance metrics. |

| Consistency in production | 12-16% increase in circuit performance. |

By combining advanced materials with precise engineering, cone crusher components deliver exceptional performance. This combination not only improves crushing accuracy but also ensures that the machine meets the demands of various applications.

The materials used in cone crushers are vital for their durability and efficiency. Manganese steel, carbon steel, ceramic composites, and cast steel ensure these machines can handle tough applications and resist wear over time.

- Cone crushers improve energy efficiency by 10-30%, reducing operational costs.

- Crushers maintain consistent productivity for the same material size, even with variations in chamber design.

- Industry experts emphasize optimizing wear parts and chamber configurations for better performance and longevity.

Proper material selection not only enhances crusher reliability but also supports the mining industry’s demand for processing over 1.3 million tons of stone annually. By balancing design and operational variables, cone crushers deliver consistent results across diverse applications.

FAQ

What are the most important cone crusher components?

The mantle, concaves, main shaft, eccentric bushing, and frame are key components. Each part plays a vital role in the crushing process.

How do materials affect the performance of cone crusher components?

High-quality materials improve durability, reduce wear, and enhance efficiency. They ensure the crusher operates smoothly, even under tough conditions.

Why is manganese steel commonly used in cone crusher components?

Manganese steel hardens under stress, making it ideal for crushing abrasive materials. Its durability extends the lifespan of critical parts like the mantle and concaves.

Post time: Jun-03-2025