A jaw crusher serves a crucial role in material reduction, breaking down large rocks into smaller, manageable sizes for industrial applications. It operates by using compressive force to crush materials between two plates—one fixed and one moving—powered by a jaw crusher shaft. This mechanism ensures efficient processing of raw materials, making jaw crushers indispensable in mining, construction, and recycling industries.

Key trends highlight their growing importance:

- Rapid industrialization and urbanization drive demand for jaw crusher plants.

- Mobile jaw crushers are replacing traditional models for on-site crushing solutions.

- Rising construction activities in emerging economies fuel infrastructure development.

Jaw crushers also contribute to sustainability. They help recycle concrete and stone, reducing waste and reusing materials in new projects. In mining, they handle primary size reduction with jaw plate for crusher, ensuring smooth downstream processing. Their versatility and reliability, along with essential jaw crusher parts, make them a cornerstone of industrial material handling, particularly with the innovative jaw crusher plate middle design enhancing their performance.

Key Takeaways

- Jaw crushers break big rocks into smaller ones. They are important in mining, building, and recycling.

- The V-shaped crushing area helps crush rocks better and faster.

- Checking jaw plates often keeps the crusher working well and avoids big repairs.

- New smart tech will make jaw crushers work better and cost less.

- Eco-friendly designs, like electric models, help protect the environment.

What is a Jaw Crusher?

Definition and Purpose

A jaw crusher is a mechanical device designed to break down large rocks and materials into smaller, manageable pieces. It achieves this by using two jaws—one fixed and one movable—that work together to crush materials through compressive force. The movable jaw swings back and forth, mimicking the motion of a nutcracker, while the fixed jaw remains stationary. This crushing action makes jaw crushers ideal for handling hard and abrasive materials, such as ores and construction debris.

Jaw crushers are commonly used as primary crushers in mining, construction, and recycling industries. Their reliability and ability to process tough materials make them indispensable for reducing raw materials into sizes suitable for further processing.

Note: Jaw crushers play a vital role in sustainable practices by enabling the recycling of construction materials, contributing to the circular economy.

Key Components Overview

Jaw crushers consist of several essential components that work together to ensure efficient operation. These components include:

- Jaws: The fixed jaw remains stationary, while the movable jaw crushes materials against it.

- Crushing Chamber: A V-shaped design allows materials to enter wide at the top and exit narrow at the bottom.

- Flywheel: Stores energy to maintain smooth and continuous movement of the jaw plates.

- Elbow Plate: Absorbs impact loads and keeps the jaw plates in position.

- Eccentric Shaft: Converts motor energy into the reciprocating motion of the movable jaw.

| Feature | Description |

|---|---|

| Jaws | Fixed and movable jaws; fixed jaws are stationary while movable jaws crush materials. |

| Crushing Chamber | V-shaped design that allows material to enter wide and be crushed before exiting narrow. |

| Flywheel | Stores energy for smooth and continuous jaw plate movement. |

| Elbow Plate | Maintains jaw plate position and absorbs impact loads. |

| Eccentric Shaft | Converts motor energy into reciprocating motion of the movable jaw plate. |

| High Efficiency | Achieves processing capacity of hundreds of tons per hour through extrusion crushing principle. |

| Versatility | Capable of handling hard ores up to 7 on the Mohs hardness scale with specific jaw plate materials. |

| Simple Structure | Composed of four main components: frame, movable jaw assembly, eccentric shaft, and elbow plate. |

| High Cost-Effectiveness | Purchase cost is 20%-30% lower than that of impact crushers under the same capacity conditions. |

| Adjustable Size | Discharge opening size can be set flexibly between 10-150mm using adjusting devices. |

These components work in harmony to deliver high efficiency, versatility, and cost-effectiveness, making jaw crushers a preferred choice for industrial applications.

Role in Material Crushing

Jaw crushers excel in material crushing by using the extrusion principle. The movable jaw presses materials against the fixed jaw, applying compressive force to break them into smaller pieces. This process is highly effective for reducing hard ores, rocks, and construction debris.

The crushing chamber’s V-shaped design ensures that materials enter wide at the top and exit narrow at the bottom, facilitating efficient size reduction. The adjustable discharge opening allows operators to control the output size, ranging from coarse fragments to finer granularity.

Performance statistics highlight the importance of jaw crushers in material crushing:

- Throughput: Measured in tons per hour (TPH), jaw crushers can process hundreds of tons of material depending on their size and settings.

- Efficiency: Factors like rotational speed, crusher geometry, and power ratings directly impact TPH output.

- Material Characteristics: Hardness and moisture content influence crushing efficiency, with harder materials requiring more effort.

Jaw crushers also contribute to operational sustainability by enabling the recycling of construction materials. Their ability to handle diverse feed materials, including hard ores and demolition debris, underscores their versatility and importance in modern industries.

Jaw Crusher Plate Middle and Working Principle

Crushing Mechanism

The crushing mechanism of a jaw crusher relies on the interaction between the fixed and movable jaw plates. The movable jaw plate moves in a reciprocating motion, powered by the eccentric shaft. This motion presses materials against the fixed jaw plate, applying compressive force to break them into smaller pieces. The “Jaw Crusher Plate Middle” plays a critical role in this process, as it ensures even distribution of force across the crushing chamber.

The V-shaped design of the crushing chamber enhances efficiency by guiding materials toward the narrow bottom, where the final crushing occurs. This design minimizes energy loss and ensures consistent material size. Operators can adjust the discharge opening to control the output size, making the jaw crusher adaptable to various applications.

Tip: Regular inspection of the jaw plates can prevent uneven wear, which may reduce crushing efficiency over time.

Material Feeding and Discharge

Proper material feeding and discharge significantly impact the performance of a jaw crusher. Feeding materials in a controlled manner ensures smooth operation and prevents clogging. The “Jaw Crusher Plate Middle” facilitates efficient material flow by maintaining a balanced crushing chamber.

The following table highlights best practices for feeding and discharge and their effects on efficiency:

| Practice | Impact on Efficiency |

|---|---|

| In-line Feeding | Limits opportunities for material to clog the Jaw Crusher, enhancing flow and reducing downtime. |

| Choke Feeding | Maintains a crushing chamber that is at least 80% full, improving material shape and overall efficiency. |

| Removal of Oversized Materials | Prevents clogging and blockage of the crusher opening, ensuring consistent production rates. |

| Scalping Fines | Reduces clogging in the chamber, prolongs wear component life, and maintains consistent product shape. |

Efficient discharge is equally important. The adjustable discharge opening allows operators to control the size of the crushed material. This flexibility ensures that the jaw crusher meets the specific requirements of different projects, from coarse aggregates to finer materials.

Importance of the Toggle Plate

The toggle plate serves as a vital component in the operation of a jaw crusher. It acts as a safety mechanism, preventing damage to the crusher in case of uncrushable material entering the chamber. The toggle plate also transfers force from the eccentric shaft to the movable jaw, enabling the crushing action.

Recent advancements have improved the functionality of toggle plates. Adjustable toggle plates with hydraulic mechanisms allow operators to make quick adjustments, enhancing operational flexibility. The table below outlines the importance of toggle plates in jaw crusher performance:

| Evidence Type | Description |

|---|---|

| Efficiency Improvement | Customization of toggle plates can significantly enhance operational efficiency based on material characteristics. |

| Safety Compliance | High-quality toggle plates from reputable manufacturers ensure adherence to safety standards, reducing machinery-related accidents. |

| Technological Advancements | Innovations like adjustable toggle plates with hydraulic mechanisms allow for quick adjustments to meet changing operational needs. |

The “Jaw Crusher Plate Middle” works in conjunction with the toggle plate to ensure smooth and efficient crushing. Together, these components contribute to the durability and reliability of the jaw crusher, making it a preferred choice in various industries.

Types of Jaw Crushers

Single-Toggle Jaw Crushers

Single-toggle jaw crushers feature a straightforward design that makes them lightweight and easy to maintain. These crushers use a single pivot point, allowing the movable jaw to swing in an arc-like motion. This design reduces the number of moving parts, enhancing reliability and simplifying maintenance tasks.

- Advantages:

- High crushing efficiency and capacity.

- Lower weight compared to other models.

- Ideal for mining and construction applications.

The simplicity of single-toggle jaw crushers makes them popular in regions with extensive mining activities. Their ability to handle tough materials efficiently ensures consistent performance in demanding environments.

Tip: Regular lubrication of the pivot point can extend the lifespan of single-toggle jaw crushers and maintain their efficiency.

Double-Toggle Jaw Crushers

Double-toggle jaw crushers are designed for durability and heavy-duty applications. They use two toggle plates, which create a more complex motion for the movable jaw. This design enhances crushing force, making these crushers suitable for processing tough and abrasive materials.

| Study Title | Focus | Key Findings |

|---|---|---|

| Dynamic Analysis of Double Toggle Jaw Crusher Using Pro | Design and efficiency of double-toggle jaw crushers | Emphasizes weight reduction and energy savings in swing plate design, with potential weight savings of 10-25%. |

| Design and Finite Element Analysis of Swing Jaw Plate of Jaw Crusher with Stiffener | Comparison of single toggle and composite jaw crushers | Highlights deformation and stress comparisons, showing advantages of composite materials over traditional manganese steel. |

Double-toggle jaw crushers are heavier and more complex than single-toggle models, but their robust design ensures reliable operation in industries requiring high crushing power.

Overhead Eccentric Jaw Crushers

Overhead eccentric jaw crushers utilize an eccentric shaft to create a circular motion for the movable jaw. This design improves feeding action and enhances the efficiency of the crushing process.

- Design Benefits:

- Lighter weight for portable use.

- Lower cost compared to other models.

- Efficient crushing due to elliptical wiping motion.

| Design Benefits | Applications |

|---|---|

| Lighter weight | Portable use |

| Lower cost | Efficient crushing process |

| Good feeding action | Suitable for various rock types |

Overhead eccentric jaw crushers are ideal for applications requiring mobility and versatility. However, the increased motion can accelerate wear on jaw plates, requiring regular inspection and replacement.

Note: Overhead eccentric designs are less common but offer unique advantages for specific industrial needs.

Components of a Jaw Crusher

Fixed and Moving Jaw Plates

The fixed and moving jaw plates are essential components of a jaw crusher. The fixed jaw plate remains stationary, while the moving jaw plate oscillates to crush materials. Together, they form the crushing chamber, where the material is reduced in size. The “Jaw Crusher Plate Middle” ensures even force distribution across the chamber, enhancing efficiency and reducing wear.

Comparative studies highlight the importance of jaw plate design. For instance:

| Study Title | Key Findings |

|---|---|

| A Review on Study of Jaw Plates of Jaw Crusher | Potential weight savings of 10-25% through design improvements. |

| Application of The New Shape Crushing Plate | Assesses the suitability of new plate profiles for better performance. |

Regular inspection and maintenance of jaw plates are crucial. Uneven wear can reduce crushing efficiency and increase operational costs.

Tip: Replacing worn plates promptly ensures consistent performance and prevents damage to other components.

Toggle Plate and Pitman

The toggle plate and pitman play a critical role in the jaw crusher’s operation. The toggle plate acts as a safety mechanism, designed to break if uncrushable material enters the chamber. This prevents severe damage to the pitman and other components. Additionally, the toggle plate transfers force from the eccentric shaft to the moving jaw, enabling the crushing action.

The pitman supports the moving jaw and defines the crusher’s stroke. Its robust design ensures durability and operational efficiency. Key functions include:

- Safety: The toggle plate protects the pitman and frame from damage.

- Support: It provides a seat for the pitman and helps define the crusher’s motion.

- Efficiency: Together, the toggle plate and pitman ensure smooth operation and consistent crushing performance.

| Component | Function | Importance |

|---|---|---|

| Toggle Plate | Acts as a sacrificial link to protect the pitman and frame from damage. | Essential for safety; prevents severe damage to other components. |

| Pitman | Provides support and defines the crusher’s stroke. | Critical for the operational efficiency of the jaw crusher. |

Flywheel and Eccentric Shaft

The flywheel and eccentric shaft are vital for the jaw crusher’s efficiency. The flywheel stores energy and counterbalances the eccentric shaft, ensuring smooth and continuous motion. This reduces friction losses and enhances the crusher’s overall performance.

The eccentric shaft creates the motion necessary for the moving jaw. It converts motor energy into the reciprocating motion required for crushing. Together, these components contribute to power savings and operational efficiency.

| Component | Role in Efficiency |

|---|---|

| Flywheel | Counterbalances the eccentric shaft, enabling a true circular motion and reducing friction losses. |

| Eccentric Shaft | Creates the motion necessary for the screen, contributing to power savings and overall efficiency. |

Note: Regular lubrication of the eccentric shaft and inspection of the flywheel can prevent mechanical failures and ensure optimal performance.

Applications and Advantages

Industries Using Jaw Crushers

Jaw crushers find applications across several industries due to their ability to handle diverse materials efficiently. These crushers are widely used in:

- Mining: They break down large rocks and ores into smaller sizes for further processing.

- Construction: Jaw crushers recycle materials like concrete and asphalt, reducing waste and enabling reuse in new projects.

- Recycling: They convert waste materials into usable products, contributing to sustainable practices.

Market reports highlight their growing demand in the construction sector, driven by urbanization and infrastructure development. Companies like Epiroc and McCloskey tailor jaw crushers for specific needs, such as urban construction or large-scale mining. Additionally, stringent environmental regulations in developed markets encourage the adoption of eco-friendly crushers, creating opportunities for innovative manufacturers.

| Industry | Application |

|---|---|

| Mining | Crushing ores and rocks for further processing. |

| Construction | Recycling concrete and asphalt for reuse in new projects. |

| Recycling | Converting waste materials into usable products. |

Benefits Over Other Crushers

Jaw crushers offer several advantages compared to other crushing solutions. They handle a variety of materials, including hard granite and reclaimed asphalt pavement, with less wear than primary impact-style crushers. Their compact size makes them suitable for tight spaces, such as underground mining and mobile applications.

Key benefits include:

- Minimal Fine Materials: Jaw crushers produce less dust and fine particles, ensuring cleaner operations.

- Cost Efficiency: Lower equipment depreciation and maintenance costs make them a cost-effective choice.

- Versatility: They adapt to various materials and applications, from mining to recycling.

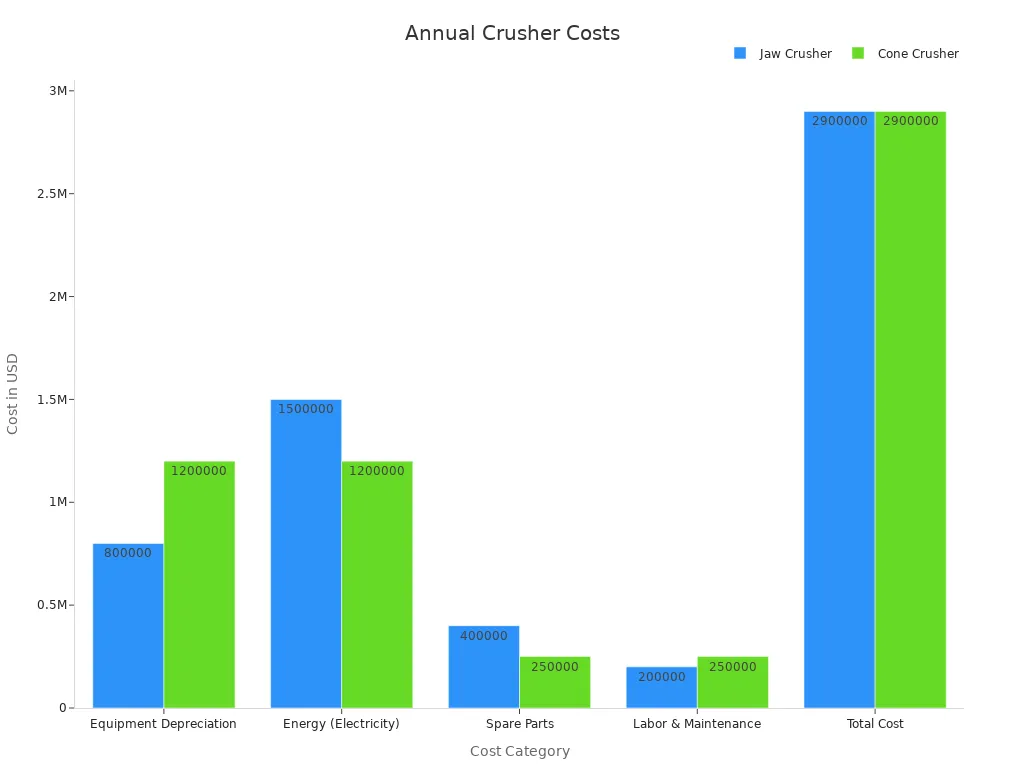

| Category | Jaw Crusher (Annual) | Cone Crusher (Annual) |

|---|---|---|

| Equipment Depreciation | $800,000 | $1,200,000 |

| Energy (Electricity) | $1,500,000 | $1,200,000 |

| Spare Parts | $400,000 | $250,000 |

| Labor & Maintenance | $200,000 | $250,000 |

| Total Cost | $2,900,000 | $2,900,000 |

Versatility and Efficiency

Jaw crushers excel in versatility and efficiency, making them indispensable in various industries. Their adjustable settings allow operators to modify the final particle size by changing the gap between crushing plates. This adaptability ensures suitability for secondary or tertiary crushing.

Efficiency assessments confirm their ability to operate continuously with minimal downtime, enhancing productivity. Jaw crushers also handle a wide range of materials, including ores, construction waste, and aggregates, demonstrating their broad applicability.

| Metric | Description |

|---|---|

| Efficiency | High efficiency in breaking down materials, suitable for secondary or tertiary crushing. |

| Adjustable Settings | Ability to modify final particle size by changing the gap between crushing plates. |

| Productivity | Capable of continuous operation with minimal downtime, enhancing overall productivity. |

| Versatility | Adaptable to various materials, including ores, construction waste, and aggregates. |

| Industry Applications | Used in mining, construction, and recycling, demonstrating its broad applicability. |

Jaw crushers combine efficiency, adaptability, and cost-effectiveness, making them a preferred choice for industrial applications.

Future Trends in Jaw Crushers (2025)

Automation and Smart Technology

Jaw crushers in 2025 will embrace advanced automation and smart technology to enhance efficiency and reduce operational costs. Artificial intelligence (AI) will enable real-time monitoring of crusher performance, identifying potential issues before they escalate. Predictive maintenance systems will minimize downtime by scheduling repairs based on machine usage and wear patterns. Machine learning algorithms will optimize operations, ensuring precision and reducing human error.

Manufacturers will also integrate digital twins and cloud-based analytics to improve workflows. These tools will allow operators to simulate crusher performance and make data-driven decisions. Mobile app-based platforms will provide users with remote access to machine diagnostics, improving customer service and lifecycle management. Modular design frameworks will simplify assembly and customization, catering to diverse industrial needs.

Sustainability and Energy Efficiency

Environmental concerns will drive the adoption of sustainable practices in jaw crusher design. Electric and hybrid models will replace traditional diesel-powered crushers, reducing carbon emissions and meeting stricter environmental regulations. Energy-efficient components, such as advanced motors and optimized crushing chambers, will lower power consumption without compromising performance.

Recycling capabilities will also improve. Jaw crushers will process construction debris more effectively, contributing to the circular economy. The “Jaw Crusher Plate Middle” will play a crucial role in enhancing material flow, ensuring efficient recycling operations. These advancements will align with global sustainability goals, making jaw crushers an eco-friendly choice for industries.

Enhanced Durability and Maintenance

Future jaw crushers will feature enhanced durability to withstand demanding applications. High-strength materials and innovative designs will extend the lifespan of critical components, such as jaw plates and toggle plates. Improved wear resistance will reduce the frequency of replacements, lowering maintenance costs.

Maintenance processes will become more user-friendly. Hydraulic systems will simplify adjustments, while automated alerts will notify operators of necessary repairs. These innovations will ensure consistent performance and reduce downtime, making jaw crushers more reliable than ever.

Jaw crushers remain essential tools in industries like mining, construction, and recycling. Their ability to handle diverse materials efficiently stems from key components such as jaw plates, toggle plates, and flywheels. Each crusher model has unique requirements, including specific jaw plate designs and mounting methods, tailored to its intended application. High wear resistance materials ensure durability, especially when processing abrasive materials.

Modern jaw crushers prioritize energy efficiency, sustainability, and compliance with environmental standards. Innovations like automation and advanced materials enhance performance while reducing maintenance needs. These advancements position jaw crushers as indispensable in meeting industrial demands and achieving sustainable practices.

Note: Selecting the right crusher involves balancing capacity, budget, and technical requirements to ensure optimal performance.

FAQ

What materials can a jaw crusher process?

Jaw crushers handle a wide range of materials, including hard rocks, ores, concrete, and construction debris. They are ideal for crushing abrasive materials like granite and basalt, as well as softer materials like limestone. Their versatility makes them suitable for mining, construction, and recycling industries.

How often should jaw plates be replaced?

The frequency of jaw plate replacement depends on material hardness and crusher usage. Operators should inspect plates regularly for wear. Replacement is necessary when plates show significant wear or uneven surfaces, as this ensures consistent performance and prevents damage to other components.

What is the role of the toggle plate in a jaw crusher?

The toggle plate acts as a safety mechanism and a force transmitter. It protects the crusher from damage by breaking if uncrushable material enters the chamber. Additionally, it transfers force from the eccentric shaft to the movable jaw, enabling the crushing action.

How does automation improve jaw crusher performance?

Automation enhances performance by enabling real-time monitoring and predictive maintenance. Smart systems identify potential issues early, reducing downtime. Automated adjustments optimize operations, ensuring consistent output and efficiency. These advancements make crushers more reliable and cost-effective.

Can jaw crushers contribute to sustainability?

Jaw crushers support sustainability by recycling construction materials like concrete and asphalt. They reduce waste and enable the reuse of materials in new projects. Energy-efficient models and electric-powered crushers further minimize environmental impact, aligning with global sustainability goals.

Post time: Jun-05-2025