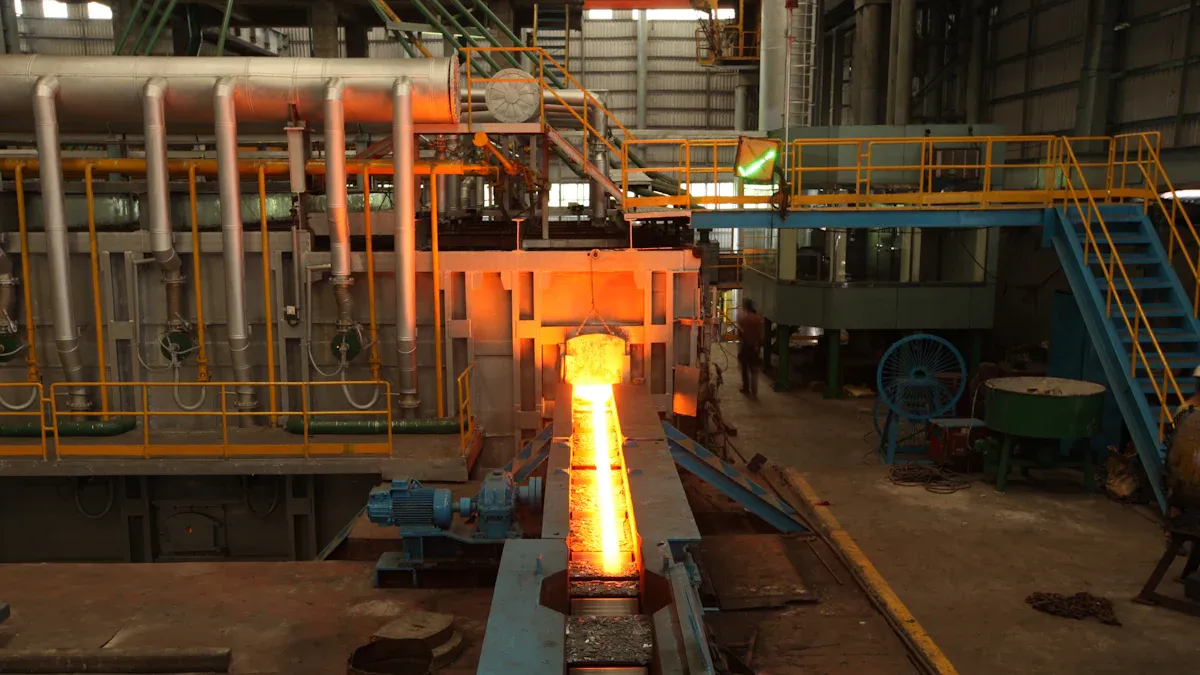

Heat-resistant steel plays a crucial role in cement mines. This type of steel withstands high temperatures, making it essential for safety and efficiency. Its unique properties help prevent equipment failure in extreme conditions. Neglecting heat-resistant steel can lead to significant operational risks. For instance, components like the Jaw Crusher Jaw Plate and Crusher Rotor require this material to function effectively. Additionally, using Carbon Manganese Steel in Jaw Crusher Wear Parts ensures durability and performance.

Key Takeaways

- Heat-resistant steel is crucial for safety and efficiency in cement operations. It prevents equipment failures in high-temperature environments.

- Using heat-resistant steel increases equipment durability. This leads to fewer breakdowns and less downtime, ensuring consistent performance.

- Investing in heat-resistant steel can save money in the long run. Although it may cost more initially, it reduces maintenance and replacement costs.

- Neglecting heat-resistant steel can result in serious risks, including equipment failures and safety hazards for workers.

- Staying updated on trends in heat-resistant steel, like advanced alloys and 3D printing, can help improve operational efficiency and safety.

Properties of Heat-Resistant Steel

Heat-resistant steel possesses unique properties that make it essential for high-temperature operations in cement production. Understanding these properties helps stakeholders appreciate its importance in maintaining safety and efficiency.

Key Physical and Chemical Properties

The effectiveness of heat-resistant steel stems from its mechanical and chemical characteristics. The following table summarizes these properties:

| Property Type | Description |

|---|---|

| Mechanical Properties | Includes hardness, tensile strength, impact resistance, creep resistance, and fatigue properties. |

| Chemical Composition | Influences thermal conductivity, thermal expansion, and oxidation resistance. |

| Microstructural Stability | Essential for maintaining strength and durability at high temperatures. |

| Corrosion Resistance | Resistance to oxidation and corrosion in high-temperature environments. |

| Thermal Properties | High heat capacity with minimal linear thermal expansion. |

Different types of heat-resistant steel exhibit varying properties. For instance:

- Ferritic: Not suitable for high-temperature applications due to insufficient strength.

- Martensitic: Offers good strength and hardness at elevated temperatures.

- Austenitic: Commonly used for valves due to high corrosion resistance and strength at high temperatures.

Maximum Operating Temperatures

Heat-resistant steel can withstand extreme temperatures, making it superior to many other steel alloys. The following table compares the maximum operating temperatures of various alloys used in cement production:

| Alloy Type | Maximum Operating Temperature |

|---|---|

| Heat-Resistant Steel | N/A |

| Austenitic Stainless Steel | Up to 1050°C |

| Titanium | Up to 600°C |

Alloying Elements

The heat resistance of steel also depends on specific alloying elements. These elements enhance the steel’s performance in high-temperature environments. The table below highlights key alloying elements and their contributions:

| Alloying Element | Contribution to Heat Resistance |

|---|---|

| Chromium | Enhances hardenability, oxidation resistance, and reduces scale formation. Requires approx 13% for corrosion resistance. |

| Molybdenum | Improves hardenability and corrosion resistance, often used with chromium in high-alloy steels. |

| Nickel | Increases impact strength and toughness, especially at low temperatures. |

| Tungsten | Improves toughness, inhibits grain growth, and enhances high-temperature strength and wear resistance. |

Benefits of Heat-Resistant Steel in High-Temperature Operations

Heat-resistant steel offers numerous advantages in high-temperature cement operations. Its unique properties enhance safety, efficiency, and equipment longevity. Here are some key benefits:

- Enhanced Worker Safety:

Heat-resistant conveyor belts play a vital role in maintaining safety in high-temperature environments. These belts endure extreme heat, reducing the risk of accidents caused by belt failures. By ensuring reliability, they create a safer working environment for employees in cement plants. - Increased Equipment Durability:

Equipment made from heat-resistant steel can withstand harsh conditions. This durability leads to fewer breakdowns and less downtime. Operators can rely on their machinery to perform consistently, even under high stress. - Improved Operational Efficiency:

Using heat-resistant steel allows for higher operating temperatures. This capability can lead to increased production rates. When equipment operates efficiently, it maximizes output and minimizes energy consumption. - Cost Savings:

Although heat-resistant steel may have a higher initial cost, its long-term benefits outweigh this expense. Reduced maintenance costs and fewer replacements lead to significant savings over time. Companies can allocate resources more effectively when they invest in durable materials. - Versatility in Applications:

Heat-resistant steel is suitable for various applications within cement operations. From kiln linings to structural components, its adaptability makes it a preferred choice. This versatility allows companies to standardize materials across different equipment, simplifying inventory management.

Case Studies of Heat-Resistant Steel in Cement Mines

Several documented case studies illustrate the significant impact of heat-resistant steel on operational efficiency in cement mines. These examples showcase how proper material selection can enhance performance and safety.

One notable case involved a material analysis of a worn drag chain link. The analysis revealed that the worn sample consisted of manganese steel, which had a microstructure typical for this material. Understanding these material properties allowed engineers to select more appropriate alloys for improved service life.

| Evidence Description | Findings | Implications for Operational Efficiency |

|---|---|---|

| Material analysis of worn drag chain link | The worn sample was identified as manganese steel. | Understanding the material properties helps in selecting alloys. |

| Selection of new alloy based on service conditions | A new alloy was implemented for the drag chain. | Enhanced alloy selection can maximize service life in high temperatures. |

| Continuous design improvements based on wear studies | Suppliers inspect worn components for design enhancements. | This practice ensures new drag chains outperform previous ones. |

In another case, engineers selected a new alloy based on specific service conditions. This decision led to the implementation of a more durable drag chain. The new alloy significantly improved the chain’s performance in high-temperature environments.

Additionally, continuous design improvements based on wear studies have proven beneficial. Suppliers regularly inspect worn components to inform design enhancements. This proactive approach aims to ensure that each new drag chain strand outperforms the previous one in terms of durability.

These case studies demonstrate the critical role of heat-resistant steel in enhancing operational efficiency. By selecting the right materials and continuously improving designs, cement operations can achieve greater reliability and safety.

Risks of Neglecting Heat-Resistant Steel

Neglecting heat-resistant steel in cement operations can lead to severe consequences. The absence of this critical material increases the likelihood of equipment failures, which can disrupt production and compromise safety. Here are some significant risks associated with ignoring heat-resistant steel:

- Increased Equipment Failures:

Without heat-resistant steel, equipment such as rotary kilns and ball mills becomes vulnerable to wear and tear. Common failures include:- Rotary Kiln Failures: Refractory lining wear, kiln shell deformation, and drive failures.

- Ball Mill Failures: Bearing failures, liner wear, and gearbox problems.

The table below summarizes the common issues observed in cement operations lacking heat-resistant steel:

Failure Category Common Issues Diagnostic Approaches Rotary Kiln Failures Refractory lining wear, kiln shell deformation, kiln drive failures Vibration analysis, thermography, ultrasonic testing Ball Mill and Grinding Unit Failures Bearing failures, liner wear, gearbox problems, electrical problems Oil analysis, acoustic emission monitoring Preheater and Cyclone Blockages Material build-up, cyclone wear Pressure drop monitoring, endoscopic inspections, heat flow analysis Clinker Cooler Malfunctions Grate plate damage, fan failures, airflow imbalance Airflow monitoring, wear plate inspections, fan vibration analysis Conveyor System Failures Belt misalignment, belt tear and slippage, motor and drive issues Belt monitoring systems, thermal imaging, load analysis - Financial Losses:

Unplanned shutdowns due to inadequate heat resistance can be costly. A cement plant can lose up to $300,000 per day for a 1 million tons per annum (MTPA) facility. These costs can escalate due to urgent sourcing of spare parts, further extending downtime. Maintenance practices have shifted from being viewed as a cost center to a source of profitability, highlighting the importance of effective maintenance. - Safety Hazards:

Equipment failures can pose serious safety risks to workers. A malfunctioning conveyor system or kiln can lead to accidents, injuries, or even fatalities. Ensuring the use of heat-resistant steel helps mitigate these risks and promotes a safer working environment.

Future Trends in Heat-Resistant Steel Applications

The future of heat-resistant steel applications in cement operations looks promising. Innovations in material science continue to enhance the performance of heat-resistant steel. Here are some key trends to watch:

- Advanced Alloys: Researchers are developing new alloys that improve heat resistance and durability. These alloys can withstand even higher temperatures, making them suitable for extreme conditions in cement production.

- 3D Printing: The adoption of 3D printing technology allows for the creation of complex components using heat-resistant steel. This method reduces waste and enables manufacturers to produce parts with intricate designs that traditional methods cannot achieve.

- Smart Materials: The integration of sensors into heat-resistant steel components can provide real-time data on temperature and stress levels. This information helps operators monitor equipment health and prevent failures before they occur.

- Sustainability Initiatives: As the industry shifts towards sustainability, manufacturers are exploring eco-friendly production methods for heat-resistant steel. These methods aim to reduce carbon emissions and energy consumption during the manufacturing process.

- Enhanced Coatings: New coating technologies can further improve the performance of heat-resistant steel. These coatings enhance corrosion resistance and thermal stability, extending the lifespan of components in high-temperature environments.

Tip: Staying informed about these trends can help industry stakeholders make better decisions regarding material selection and equipment maintenance.

By embracing these advancements, cement operations can enhance safety, efficiency, and overall performance. The future of heat-resistant steel applications promises to bring significant improvements to the industry.

Heat-resistant steel plays an essential role in ensuring safety and efficiency in cement operations. Its ability to withstand high temperatures and abrasive materials is crucial for maintaining reliable equipment. Neglecting this vital material can lead to severe consequences, including increased equipment failures and financial losses.

Industry stakeholders must prioritize heat-resistant steel in their operations. By doing so, they can enhance safety, improve operational efficiency, and reduce maintenance costs.

| Key Point | Description |

|---|---|

| Role of Heat-Resistant Materials | Essential for the cement industry to withstand high temperatures and abrasive materials. |

| Importance of Conveyor Systems | Robust and reliable systems are crucial for maintaining efficiency and longevity in cement operations. |

| Growth Driver | Continuous demand for cement in construction and infrastructure projects drives the need for heat-resistant conveyor belts. |

FAQ

What is heat-resistant steel?

Heat-resistant steel is a specialized alloy designed to withstand high temperatures. It maintains strength and durability in extreme conditions, making it essential for equipment used in cement operations.

Why is heat-resistant steel important in cement operations?

Heat-resistant steel enhances safety and efficiency in cement operations. It prevents equipment failures, reduces downtime, and improves overall operational performance in high-temperature environments.

How does heat-resistant steel differ from regular steel?

Heat-resistant steel contains specific alloying elements that improve its thermal stability and oxidation resistance. Regular steel lacks these properties, making it unsuitable for high-temperature applications.

What are the common applications of heat-resistant steel in cement plants?

Common applications include kiln linings, conveyor belts, and structural components. These applications benefit from heat-resistant steel’s ability to endure extreme temperatures and abrasive materials.

How can companies ensure they use the right heat-resistant steel?

Companies should conduct thorough material analyses and consult with experts. Understanding specific operational conditions helps in selecting the most suitable heat-resistant steel for their equipment.

Post time: Nov-03-2025