Regular inspections of crusher parts, including jaw crusher parts and cone crusher spare parts, play a vital role in ensuring optimal performance and reliability. Studies indicate that insufficient maintenance of equipment like the gyratory crusher can lead to premature failures, with a significant percentage of issues traced back to a lack of inspections. Key components to inspect include hydraulic power units, oil temperatures, and bearing conditions. Regularly monitoring these elements not only prevents costly downtime but also enhances overall equipment efficiency. For instance, timely liner replacements in crushers can prevent operational losses, ultimately extending the service life of critical parts, especially those made from high manganese steel casting.

Key Takeaways

- Regular inspections of crusher parts are crucial for optimal performance and safety. Focus on wear parts, lubrication points, alignment, electrical components, and structural integrity.

- Implement a strict maintenance schedule. Conduct daily checks for loose bolts and lubrication, weekly visual inspections, and monthly mechanical system evaluations.

- Monitor for signs of wear, such as excessive vibration, noise, and visible cracks. Early detection prevents unexpected failures and costly downtime.

- Use high-quality materials for wear parts to enhance durability. Regular inspections help identify when replacements are necessary, extending the service life of critical components.

- Prioritize electrical safety during inspections. Check connections for security and ensure ground wires are intact to prevent fire hazards and ensure safe operations.

Wear Parts

Wear parts are critical components in any crusher. They experience significant wear and tear during operation. Regular inspections of these parts help maintain optimal performance and prevent unexpected failures. Key wear parts include the fixed jaw plate, movable jaw plate, and cheek plates. Each of these components plays a vital role in the crushing process.

Here is a summary of the main types of wear parts found in crushers:

| Type of Wear Part | Description |

|---|---|

| Jaw crusher wear parts | Includes fixed jaw plate, movable jaw plate, and cheek plates. |

| Fixed jaw plate | Installs in the jaw crusher body; available in one-piece and two-piece designs. |

| Movable jaw plate | Installs in the moving jaws; also available in one-piece and two-piece designs. |

| Cheek plates | Protects the side of the jaw crusher body from damage by crushed stone. |

Regular inspections of jaw crusher parts should occur every 250 operating hours. Following a strict maintenance schedule with daily, weekly, and monthly checks is essential. Operators should look for signs of excessive wear, such as:

- Excessive vibration or noise

- Visible cracks or structural damage

- Thinning wear plates and liners

- Uneven wear patterns

- Reduced throughput or oversized product

- Frequent clogging or material jams

- Increased power consumption

- Bearing overheating or lubrication issues

The lifespan of manganese parts can vary significantly, ranging from six weeks to six years, depending on the rock being processed. Choosing high-quality materials is crucial for wear parts to endure harsh conditions. Premium materials enhance resistance to abrasion, impact, and wear, leading to longer service life. Regular inspections help identify wear patterns and determine when replacements are necessary.

Implementing quality selection and regular inspections maximizes performance and durability. Proper maintenance and optimized operations are essential for cost-effectiveness. Operator training also contributes to the overall efficiency of wear parts.

Lubrication Points

Proper lubrication is essential for the efficient operation of crusher parts. Regularly checking lubrication points prevents mechanical failures and extends the lifespan of critical components. Each lubrication point has specific requirements that operators must follow to maintain optimal performance.

Here are some key lubrication points and their recommended lubricants:

| Lubrication Point | Recommended Lubricant | Notes |

|---|---|---|

| Eccentric Shaft Bearings | Jet-Lube Jet-Plex EP™ Grease | Requires mechanically stable grease for shock loading and vibration. |

| Pitman Bearings | Jet-Lube Jet-Plex EP™ Grease | Heavily loaded; grease should maintain consistency. |

| Dynamic Suspension Shaft | Intermittent grease | Lubricated without oil return; requires regular application. |

| Thrust Plate Elbow | Thick oil | Needs lubrication every 3-4 hours; different from other points. |

| Small Jaw-Type Bearing | Oil cup and lubricating oil | Can be used once every 30-40 minutes. |

Operators should schedule daily servicing and lubrication. They must check the manufacturer’s specifications for each piece of equipment. Implementing contamination control practices is also crucial. Neglecting these inspections can lead to severe consequences. For instance, premature bearing failures may occur due to inadequate lubrication. Additionally, issues like knocked-off breathers can allow dust into the oil chamber, leading to further complications.

Using the right type of lubricant is vital. Operators should consider environmental conditions such as moisture and temperature. Selecting lubricants with low-water washout and high-corrosion resistance is essential for wet environments. Higher viscosity lubricants work best for low-speed, high-load applications.

Alignment Checks

Alignment checks are essential for maintaining the efficiency and longevity of crusher parts. Proper alignment ensures smooth operation and minimizes wear on components. Regular inspections can prevent costly downtime and enhance overall performance. Here are some key alignment checks to consider:

- Belt Alignment: Proper belt alignment is crucial for optimal performance. It ensures smooth material flow and reduces downtime.

- Leveling the Crusher: Keeping the crusher level is essential for proper belt tracking. This is especially important after moving equipment.

- Idler Adjustments: If the belt runs off track, adjustments to idlers are necessary. Specific movements can correct alignment issues.

- Take-Up Extensions: Equal extension or retraction of take-ups is important for maintaining belt tension. This helps prevent slippage and wear.

- New Belt Adjustments: New belts may require multiple adjustments as they stretch and settle into place.

Misalignment can lead to several negative consequences. The table below summarizes the potential impacts of misalignment on production output and equipment longevity:

| Consequence | Description |

|---|---|

| Accelerated Wear and Tear | Misalignment causes irregular forces that lead to increased friction and contact between components. This results in faster degradation and more frequent maintenance. |

| Energy Inefficiency | Misaligned machinery requires more energy to operate. This leads to higher operational costs and reduced efficiency in production output. |

| Reduced Lifespan | Continuous exposure to excessive vibrations shortens the life expectancy of machinery. This increases the likelihood of breakdowns and downtime. |

| Safety Hazards | High vibration levels can lead to catastrophic failures. This poses risks to personnel and surrounding infrastructure. |

| Quality Control Issues | Inconsistent results from misaligned equipment can lead to substandard deliverables. This affects overall production quality. |

To perform alignment checks effectively, operators can use various tools and techniques. The following table outlines common equipment types and their importance in alignment checks:

| Equipment Type | Importance of Alignment Checks |

|---|---|

| Turbines (gas, wind, steam) | Can experience large temperature changes causing movement in piping and foundations. |

| Refrigerant Chillers | Aligned components are susceptible to unintended movement due to compressor mounting. |

| Chilled Water, Condenser Water, and Feed Water Pumps | Temperature changes can cause machine movement, especially if bases are not sufficiently massive. |

| Extruders | Large temperature swings can lead to machine movement over time. |

| Hammer Mills, Crushers | The nature of work can cause unintended movement, even when bolted. |

| Other Machines | Offers benefits like inspecting couplings and seals, and practicing with alignment tools. |

Regular alignment checks are vital for maintaining the efficiency and safety of crusher parts. Implementing a routine inspection schedule can significantly enhance equipment performance and longevity.

Electrical Components

Electrical components play a crucial role in the operation of crushers. Regular inspections of these components help prevent failures and ensure safety. Operators should focus on several key areas during their inspections.

Common electrical issues found during crusher inspections include:

- Electrical power supply problems, such as unstable voltage or no power.

- Faulty start switches or issues with the control panel.

- Blown fuses or tripped circuit breakers.

- Activated safety interlocks or emergency stops.

- Faulty wiring or connections.

- Sensor failures or communication errors in automated systems.

- Software glitches or outdated firmware.

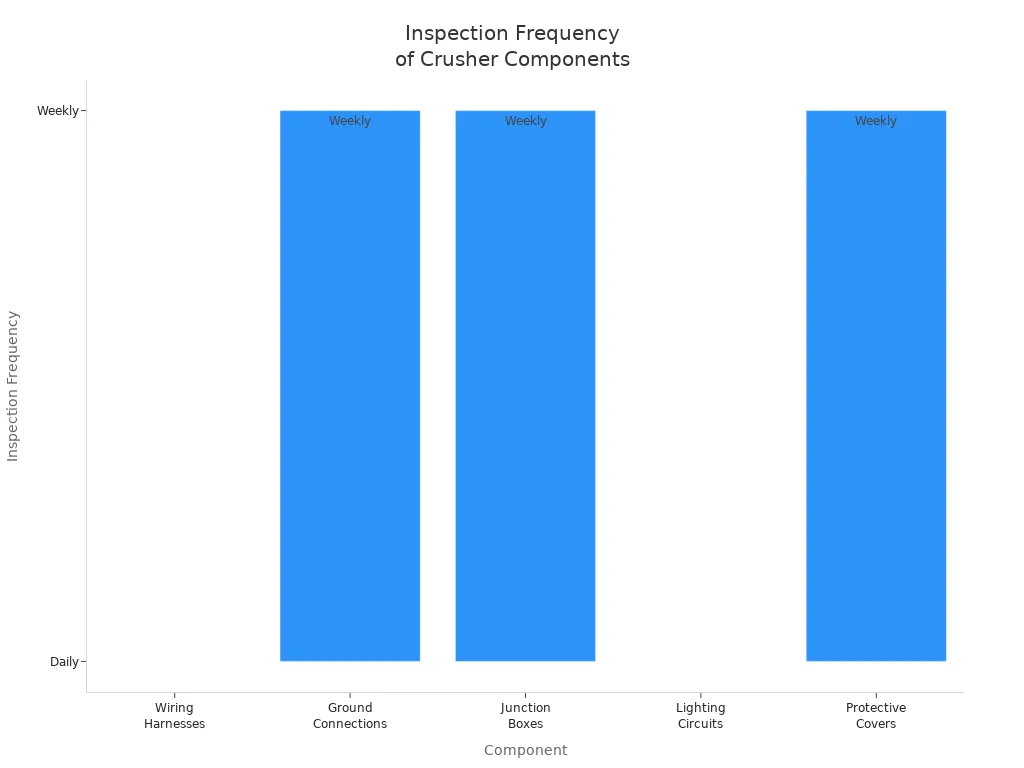

To comply with safety regulations, operators should inspect electrical components regularly. The following table outlines the recommended inspection types and frequencies:

| Component | Inspection Type | Frequency |

|---|---|---|

| Wiring Harnesses | Visual/Physical | Daily |

| Ground Connections | Resistance Test | Weekly |

| Junction Boxes | Moisture Check | Weekly |

| Lighting Circuits | Function Test | Daily |

| Protective Covers | Integrity Check | Weekly |

Inspecting electrical wiring and connections is vital. Operators should:

- Verify that electrical connections are secure before starting any equipment.

- Regularly check for loose connections or frayed wires to avoid fire hazards.

- Ensure that ground wires, motor plugs, and power cable connections are secure before operating equipment.

Neglecting these inspections can lead to serious risks. Faulty electrical equipment can cause fires, making it essential to have fire extinguishing capabilities on-site. Regular visual inspections help ensure safety and proper cable support. Additionally, electrical installation rooms must remain dry and free of combustible materials.

By prioritizing electrical component inspections, operators can enhance the safety and efficiency of their crusher operations.

Structural Integrity

Maintaining the structural integrity of crushers is crucial for safe and efficient operations. Regular inspections help identify potential issues before they escalate into catastrophic failures. Operators should focus on several key checks to ensure the structural soundness of their equipment.

Here are essential structural integrity checks for crushers:

| Check Type | Description |

|---|---|

| Bolt Torque Checks | Routine schedules for checking and re-torquing critical structural bolts are essential. |

| Crack Inspection | Periodic inspections for hairline cracks, especially around stress concentration points, are vital. |

| Lubrication | Proper lubrication with the correct type and grade prevents overheating and wear. |

| Vibration Analysis | Regular checks can detect early signs of failure before they lead to catastrophic breakdowns. |

Environmental factors such as vibration and temperature can significantly affect the structural integrity of crusher parts. Variations in temperature and external loads complicate structural dynamics, which can lead to failures. For instance, high-speed operations can cause excessive vibration, leading to structural damage. Proper lubrication is essential to mitigate these risks.

Common structural issues identified during inspections include:

- Mechanical Failures

- Bearings overheating or wearing out prematurely.

- Cracks or fractures in the crusher frame.

- Vibration and Noise

- Excessive vibration or noise during operation.

- Hydraulic System Failures

- Leakages or insufficient pressure.

Regular inspections and maintenance of structural integrity can prevent costly downtime and enhance the lifespan of crusher parts. Operators should prioritize these checks to ensure safe and efficient operations.

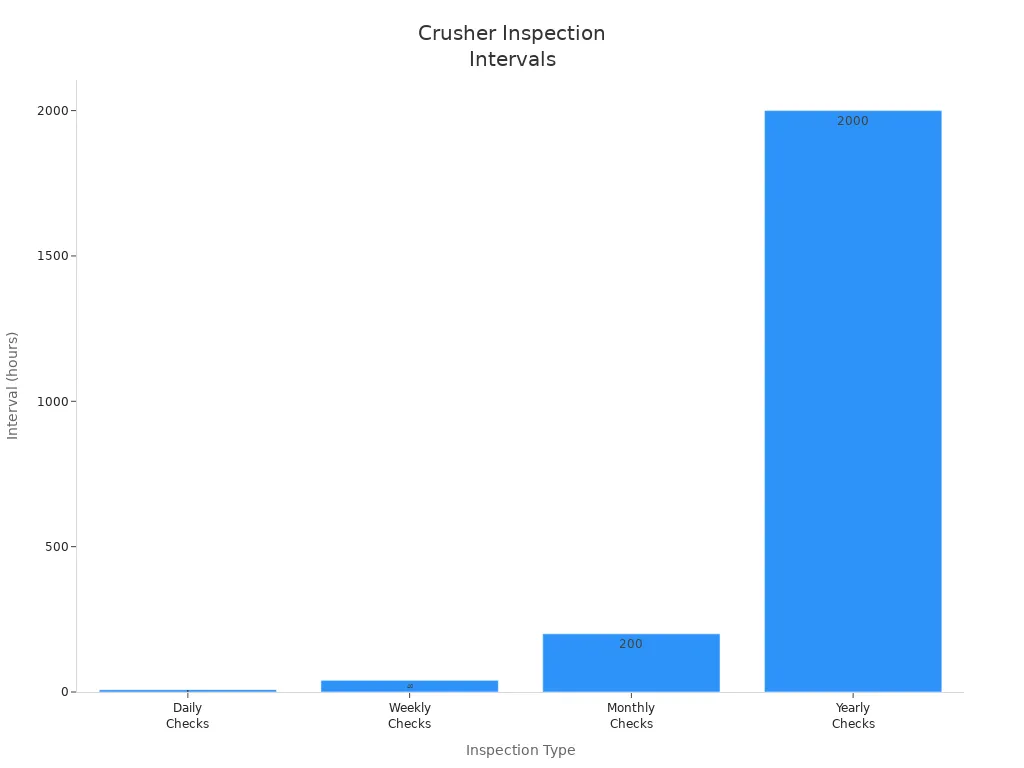

Regular inspections of crusher parts are essential for maintaining optimal performance and safety. Key inspection points include:

- Daily Inspections: Check for loose bolts, inspect jaw plates, and lubricate moving parts.

- Weekly Maintenance: Conduct visual inspections and check wear liners.

- Monthly Maintenance: Inspect mechanical systems and oil levels.

- Annual Overhaul: Disassemble and inspect wear parts for damage.

Implementing a routine inspection schedule significantly reduces downtime and repair costs. Neglecting maintenance can lead to excessive breakdowns, costing nearly $50,000 an hour. By prioritizing regular inspections, operators can enhance equipment longevity and operational efficiency.

FAQ

What are the most critical parts to inspect on a crusher?

Operators should regularly inspect wear parts, lubrication points, alignment, electrical components, and structural integrity. These areas significantly impact the crusher’s performance and longevity.

How often should I perform inspections on my crusher?

Daily inspections are essential for loose bolts and lubrication. Weekly checks should include visual inspections, while monthly maintenance focuses on mechanical systems. An annual overhaul is crucial for thorough evaluations.

What signs indicate wear on crusher parts?

Signs of wear include excessive vibration, noise, visible cracks, thinning wear plates, and uneven wear patterns. Operators should monitor these indicators to prevent unexpected failures.

Why is proper lubrication important for crushers?

Proper lubrication reduces friction and wear on moving parts. It prevents overheating and extends the lifespan of critical components, ensuring efficient operation and minimizing downtime.

How can I ensure electrical safety during inspections?

Inspect electrical connections for security and check for frayed wires. Ensure ground wires and power cable connections are intact. Regular visual inspections help maintain safety and prevent fire hazards.

Post time: Oct-17-2025