Selecting the right jaw crusher machines plays a pivotal role in operational efficiency. These machines are essential in industries like mining and construction, where they enhance productivity by breaking down large materials. Key features, such as advanced technology and design parameters, significantly impact performance and reliability. For example, machines with hydraulic drives and user-friendly control panels can boost output and reduce downtime. Additionally, understanding the various jaw crusher parts, including jaw crusher wear parts, is crucial for maintenance and longevity. Variations among brands and models, such as feed size and mobility, further influence the effectiveness of jaw crusher machines, while also considering the importance of rock crusher parts and cone crusher spare parts for overall operational success.

Key Takeaways

- Selecting the right jaw crusher enhances operational efficiency. Focus on features like crushing capacity and portability to meet your specific needs.

- High-quality materials, such as high manganese steel, improve durability and lifespan. Choose machines built with strong materials to reduce wear and tear.

- Regular maintenance is crucial for performance. Schedule inspections and keep spare parts readily available to minimize downtime and repair costs.

- Understanding the crushing capacity and reduction ratio helps in selecting the right machine. Ensure the model matches your production goals for optimal results.

- After-sales support, including warranties and training, is vital. Strong support systems enhance machine value and ensure effective operation.

Design and Build Quality of Jaw Crusher Machines

The design and build quality of jaw crusher machines significantly influence their performance and longevity. Manufacturers prioritize using high-quality materials to enhance durability. For instance, high manganese steel can provide a lifespan that is 30-50% longer compared to standard materials. This choice of material not only enhances durability but also ensures that the machines can withstand the rigors of heavy use.

Materials Used

Top manufacturers focus on innovation in product design. They invest in research and development to create advanced technology and materials. This commitment leads to jaw crusher machines that are more efficient and reliable. The hardness and abrasiveness of the feed material also play crucial roles in wear rates, influencing the lifespan of the equipment. Regular inspections can extend part life by up to 30%, increasing overall lifespan through proactive maintenance.

Structural Integrity

Structural integrity is vital for the operational success of jaw crusher machines. Strong and well-engineered frames prevent deformation under heavy loads. This quality ensures that the machines maintain their performance over time. Using wear-resistant parts can decrease replacements by 35%, reducing downtime and extending the operational lifespan. The interaction between jaw plates and material particles leads to significant wear, which can decrease efficiency and increase energy consumption.

Portability Features

Portability features are essential for many industries. A portable jaw crusher machine allows for easy transportation between job sites. This flexibility can enhance productivity and reduce operational costs. Elite manufacturers offer a wide range of crushers tailored to various tasks, indicating their understanding of diverse market needs. Additionally, strong support systems, including quick access to spare parts and maintenance, are crucial for minimizing downtime.

Performance Metrics of Jaw Crusher Machines

Performance metrics play a crucial role in evaluating jaw crusher machines. These metrics help users understand how well a machine can perform in various applications. Three key performance metrics include crushing capacity, reduction ratio, and energy efficiency.

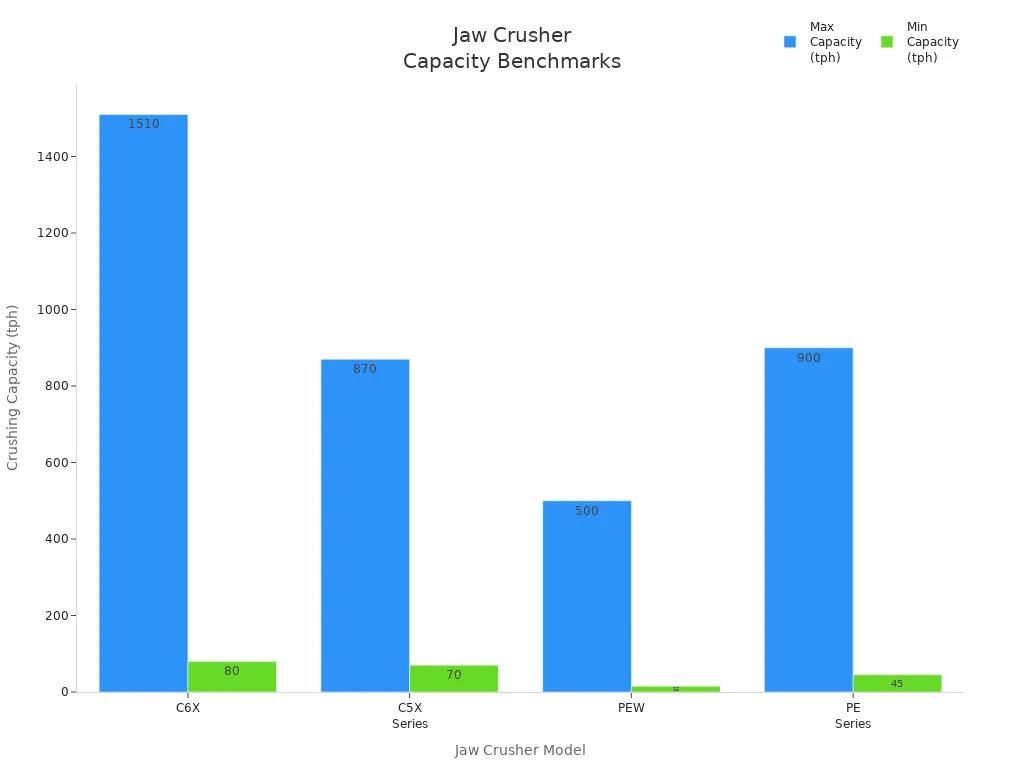

Crushing Capacity

Crushing capacity refers to the amount of material a jaw crusher can process in a given time. This metric is vital for determining the machine’s suitability for specific tasks. Different models exhibit varying capacities based on their design and operational parameters.

Here’s a table showcasing the crushing capacities of popular jaw crusher models:

| Model | Input Size | Capacity (tph) | Applications |

|---|---|---|---|

| C6X | 0-1280mm | 80-1510TPH | Large-scale mining, infrastructure projects |

| C5X Series | 0-920mm | 70-870TPH | Medium to large-scale operations |

| PEW | 80-1510TPH | 15-500TPH | Medium-scale mining, aggregate production |

| PE Series | 0-1020mm | 45-900TPH | Small to medium-scale operations |

Several factors influence crushing capacity, including:

- Design of the crusher: Different models, like Dodge and Blake types, have unique designs affecting capacity.

- Angle between the jaws: A decrease in the angle can reduce the compactness of the rock, impacting capacity.

- Speed of operation: Variations in speed can affect capacity, with different effects at slow and high speeds.

- Condition of the jaw faces: The wear and condition of the jaw faces can influence the efficiency of crushing.

- Amplitude of jaw movement: Larger amplitudes can lead to a rapid increase in theoretical tonnage, affecting actual output.

- Roughness of the jaw surface: Increased roughness can reduce the occupancy of the displacement space, impacting capacity.

Reduction Ratio

The reduction ratio measures how much a jaw crusher reduces the size of the input material. This ratio is essential for understanding the efficiency of the crushing process. Top-performing jaw crushers typically achieve a reduction ratio ranging from 6:1 to 8:1 for primary crushers, 3:1 to 5:1 for secondary crushers, and 2:1 to 3:1 for tertiary crushers.

The reduction ratio significantly influences the efficiency of jaw crushers by determining the size of the output material and the production capacity. A choke-fed chamber enhances production capacity and ensures uniform particle size. In contrast, a non-choke chamber can lead to reduced efficiency and poor particle shape.

- A choke-fed chamber maximizes production capacity and produces uniformly broken particles.

- A non-choke chamber may reduce efficiency and negatively affect particle shape.

Choke feeding jaw crushers is essential for maximizing production capacity and ensuring uniform particle breakage. Conversely, trickle feeding can lead to fewer fines but adversely affects particle shape and throughput capacity, ultimately hindering efficiency.

Energy Efficiency

Energy efficiency is a critical performance metric for jaw crusher machines. Modern advancements focus on optimizing energy consumption while maintaining high performance. Key innovations include:

- Integrated drive systems that optimize energy usage.

- Adjustable crushing parameters that reduce power consumption.

- A focus on sustainability in mining operations.

For instance, RM Group’s hybrid crushers achieve a 25% reduction in fuel costs compared to traditional models. Fuel savings can reach up to 50% when combined with hybrid screens.

Recent advancements also include:

- Hydraulic wedge settings for easy adjustments.

- High energy efficiency main motors.

- Enhanced safety and performance features.

Modern high-efficiency crushers, like the C6X, are designed to optimize energy consumption. Innovations in design lead to improved efficiency in aggregate processing.

Here’s a table comparing energy consumption rates among popular jaw crusher models:

| Compressive Strength (MPa) | Energy Consumption (Relative) |

|---|---|

| 28 | 1 |

| 90 | 4 |

These advancements contribute to reduced carbon footprints and align with tightening sustainability regulations in the industry.

Application Suitability of Jaw Crusher Machines

Jaw crusher machines excel in various applications due to their versatility and efficiency. Understanding the types of materials they process, their industry-specific applications, and their scalability and flexibility can help users make informed decisions.

Types of Materials Processed

Jaw crushers handle a wide range of materials, making them suitable for different industries. According to industry reports, the most commonly processed materials include:

| Sector | Commonly Processed Materials | Market Share (%) |

|---|---|---|

| Mining | Iron ore, coal, copper, gold-bearing materials | 68 |

| Construction | Aggregates, gravel, demolition waste | 22 |

The performance of jaw crushers varies based on the hardness of the material. For example, harder materials like granite (Mohs hardness of 7) require more energy to crush. This leads to lower throughput compared to softer materials, such as concrete (Mohs hardness of 5). Here are some insights on material hardness:

- Harder materials demand more energy, resulting in lower throughput.

- Crushing granite may yield a throughput of about 10 tons per hour (TPH).

- Softer materials like concrete can achieve around 50 TPH under similar conditions.

- Understanding the Mohs hardness scale is essential for estimating throughput and optimizing operational parameters.

Industry-Specific Applications

Jaw crusher machines serve various industries, each with unique requirements. Here are the primary applications:

- Mining Industry: Jaw crushers crush large rocks into smaller pieces, processing ores like iron, copper, gold, and silver.

- Quarrying Industry: They crush stone, concrete, and asphalt for construction projects.

- Construction Industry: Commonly used to recycle materials such as concrete and asphalt for road construction and building projects.

- Recycling Industry: Effective in crushing a variety of materials, including glass, plastic, metal, and paper, particularly in recycling difficult materials like electronic waste.

Different industries have specific application requirements. The following table summarizes these needs:

| Industry | Application Requirements | Key Functions |

|---|---|---|

| Mining | Primary crushing of hard and abrasive materials, reducing ore size for processing | Ore extraction, material handling, aggregate production, geological sampling, safety and productivity |

| Construction | Crushing concrete, bricks, stones, and other materials for infrastructure development | Demolition, road construction, foundation work, recycling, site clearing, materials handling |

| Recycling | Crushing and reducing materials like concrete and asphalt into reusable forms | Recycling operations, waste reduction, resource conservation |

Scalability and Flexibility

Scalability and flexibility are vital features of jaw crusher machines. They adapt to various operational sizes and project needs. Medium jaw crushers typically have capacities ranging from 200 to 500 tph, making them suitable for applications like quarrying and recycling. Large jaw crushers can exceed 500 tph, with some models processing up to 1,500 tph, ideal for heavy-duty applications. Factors influencing capacity include:

- Crusher size

- Feed size

- Material characteristics

- Operational parameters

- Speed of operation

- Material moisture content

Flexibility features enhance adaptability to changing project needs. For instance, the adjustable discharge opening allows control over output size. This capability enables the production of both coarse fragments and finer granularity. Here’s a summary of flexibility features:

| Feature | Description |

|---|---|

| Flexibility in Output Size | The closed side setting (CSS) can be adjusted to change the output size for various crushing needs. |

| Versatility | Suitable for tasks ranging from breaking down large rocks to producing finely crushed stone. |

Jaw crushers are known for their efficiency and adaptability, making them a preferred choice in various industrial applications due to their ability to meet changing project needs.

Maintenance Considerations for Jaw Crusher Machines

Maintaining jaw crusher machines is crucial for ensuring their longevity and performance. Proper maintenance practices can significantly reduce downtime and enhance productivity.

Ease of Maintenance

Ease of maintenance directly impacts the total cost of ownership for jaw crushers. Regular maintenance helps prevent expensive repairs and keeps machines running smoothly. Operators often face challenges, such as:

- Abnormal noise during operation, indicating loose parts or worn components.

- Reduced crushing capacity, leading to decreased productivity.

- Excessive vibration affecting stability and causing premature wear of components.

Efficient maintenance procedures can minimize these issues. Operators should prioritize easy access to internal components. Studies show that up to 40% of maintenance time can be spent on disassembly and reassembly. Simplifying this process can lead to significant time savings.

Availability of Spare Parts

The availability of spare parts is another critical factor in maintaining jaw crushers. Quick access to replacement parts ensures minimal downtime. Here’s a summary of spare parts availability for major brands:

| Brand | Availability of Spare Parts |

|---|---|

| Terex | New replacement Jaw Crusher Wear Parts available |

| Sandvik | New replacement Jaw Crusher Wear Parts available |

| Powerscreen | New replacement Jaw Crusher Wear Parts available |

| Rebel | New replacement Jaw Crusher Wear Parts available |

| Extec | New replacement Jaw Crusher Wear Parts available |

| Finlay | New replacement Jaw Crusher Wear Parts available |

Brands like GTEK Mining also offer components built for long service life, ensuring operators can find parts for daily wear or unexpected breakdowns.

Maintenance Costs

Maintenance costs can vary significantly across different manufacturers and applications. Here’s a comparison of typical maintenance costs based on application type:

| Application Type | Typical Purchase Price Range | Maintenance Costs |

|---|---|---|

| Mining and Heavy-Duty | $$$$ | Moderate to High |

| Aggregate Production | $$$ | Moderate |

| Small-Scale Construction | $$ | Low |

Annual maintenance costs for jaw crushers typically range from $15,000 to $25,000 per unit. These costs depend on usage intensity and environmental conditions. By understanding these factors, operators can make informed decisions that enhance the efficiency and reliability of their jaw crusher machines.

After-Sales Support for Jaw Crusher Machines

After purchasing a jaw crusher, after-sales support becomes crucial for maximizing its value. Strong support systems can significantly enhance operational efficiency and ensure long-term satisfaction.

Warranty and Service Agreements

Leading jaw crusher manufacturers typically offer robust warranty and service agreements. These agreements provide peace of mind and protect investments. Here’s a summary of standard warranty terms:

| Aspect | Details |

|---|---|

| Warranty Period | Two years from the date of initial commissioning. |

| Coverage | New accessories for replacement and repair if not man-made damage. |

| Technical Support | Lifetime free technical support provided. |

| Response Time | Customer issues addressed within 24 hours, resolved within 72 hours. |

Such warranties reflect manufacturers’ confidence in their products. They also ensure that customers receive timely assistance when needed.

Customer Support Availability

Customer support availability is another essential feature. Top manufacturers provide dedicated support teams to assist users. Quick responses to inquiries can minimize downtime and enhance productivity. Many companies offer multiple channels for support, including phone, email, and live chat. This accessibility ensures that operators can resolve issues efficiently, allowing them to focus on their core tasks.

Training and Resources

Training programs provided by manufacturers play a vital role in the effective use of jaw crusher machines. Well-trained operators can respond to challenges effectively. Here are some key benefits of these training programs:

- Operator training is essential for safe equipment use.

- Regular refresher courses keep operators updated on technology and safety practices.

- Training is tailored to the specific machine and jobsite.

These programs reduce errors and improve worksite safety. They also enhance equipment longevity by ensuring proper use. Operators learn to troubleshoot basic issues on-site, receiving immediate feedback that helps optimize machine operation. Investing in training not only boosts productivity but also fosters a culture of safety and efficiency.

In summary, selecting the right jaw crusher machines involves understanding several essential features. Key aspects include crushing capacity, feed size, adjustability of output, and portability. These features significantly impact operational efficiency and overall productivity.

Consider these factors when making a purchase:

- Crushing Capacity: Ensure it aligns with production goals.

- Feed Size: Match the machine to your material’s maximum size.

- Adjustability: Look for settings that allow control over output size.

- Portability: Choose based on site requirements and convenience.

By prioritizing these features, operators can make informed decisions that cater to their specific needs. Successful case studies, such as the South African mining project and the Uganda granite plant, illustrate the benefits of selecting machines based on these criteria.

FAQ

What is the primary function of a jaw crusher machine?

Jaw crusher machines primarily crush large rocks into smaller, manageable pieces. They excel in breaking down hard materials like granite, limestone, and ores, making them essential in mining and construction industries.

How do I choose the right jaw crusher for my needs?

Consider factors like crushing capacity, feed size, and material type. Evaluate your specific application requirements and select a model that aligns with your production goals and operational conditions.

What maintenance practices should I follow for jaw crushers?

Regularly inspect components for wear, ensure proper lubrication, and clean the machine to prevent debris buildup. Schedule routine maintenance to address potential issues before they escalate.

Are spare parts readily available for jaw crushers?

Yes, most reputable manufacturers provide a wide range of spare parts. Quick access to these components minimizes downtime and ensures smooth operations, enhancing overall productivity.

How can I improve the energy efficiency of my jaw crusher?

Optimize operational parameters, such as adjusting the crushing speed and feed rate. Regular maintenance and using high-efficiency models can also significantly reduce energy consumption and operational costs.

Post time: Oct-15-2025