Metso, Sandvik, Terex, Thyssenkrupp, and other trusted names lead the crusher parts industry in 2025. They offer high-quality jaw crusher machine, gyratory crusher, cone crusher parts, and crusher wear parts. Choosing these brands means fewer breakdowns and longer equipment life.

Key Takeaways

- Choose trusted brands like Metso and Sandvik for high-quality crusher parts. These brands offer durability and reduce equipment breakdowns.

- Consider total cost of ownership when selecting parts. Investing in reliable brands can save money on repairs and downtime in the long run.

- Evaluate customer support options before purchasing. Strong warranties and quick service can keep your machines running smoothly.

Quick Overview of Top Crusher Parts Brands

Metso

Metso stands out as a leader in the crusher parts industry. They offer jaw plates, mantles, and concaves that set benchmarks for durability. Their O-Series and MX wear parts help machines run longer and reduce downtime. Many operators trust Metso for consistent quality and advanced technology.

Sandvik

Sandvik has a strong reputation for reliability. They provide a wide range of crusher parts, using unique alloy compositions for extra-long wear life.

“We are regularly reviewing our distribution network and adding dealers or extending the reach of current dealers to better cover all major markets. Some examples of newer dealers include Alta Equipment in the US, Ferronordic in Germany and Kazakhstan, Eltrak in Bulgaria, SVF in Mexico, and Escandinavia in Argentina.”

Sandvik’s robust supply chain and global dealer network make their parts easy to find, no matter where a project is located.

Terex

Terex is known for innovation and performance. Their crusher parts, such as blow bars, jaw dies, and mantles, use advanced metallurgy and design. Terex parts work in both mining and construction.

Here’s a look at common applications:

| Industry | Application Description |

|---|---|

| Construction | Concrete aggregate production, roadbed paving, asphalt mixture |

| Mining | Primary ore processing, ore dressing pretreatment, tailings treatment |

Terex helps customers get the most out of their equipment in many different industries.

Thyssenkrupp

Thyssenkrupp focuses on high performance and reliability. They use advanced materials and manufacturing techniques for mantles, concaves, and jaw plates.

Their crusher parts meet strict quality standards:

| Certification | Description |

|---|---|

| ISO 9001 | Quality Management |

| ISO 14001 | Environmental Management |

Many customers choose Thyssenkrupp for their commitment to quality and environmental responsibility.

SBM

SBM offers a broad selection of crusher parts for various machines. They focus on cost-effective solutions and reliable performance. Many operators appreciate SBM’s ability to deliver parts quickly and keep machines running.

Astec Industries

Astec Industries brings advanced technology to the crusher parts market.

- The Kodiak Plus® K300 Cone Crusher features remote adjustment and automatic tramp iron relief.

- The Kodiak® K350+ cone crusher improves sand production and efficiency.

- The S-Series offers competitively-priced cone liners and jaw dies, developed by experts.

Astec’s focus on innovation helps customers boost productivity.

McCloskey International

McCloskey International designs crusher parts for tough jobs. Their parts use high-quality materials and innovative features.

| Feature | Description |

|---|---|

| High-Quality Materials | Durable materials withstand harsh conditions. |

| Innovative Design | Hydraulic adjustment systems improve reliability. |

| Heavy-Duty Feeding Systems | Built for demanding environments. |

| High-Speed Crushing Chambers | Efficient processing increases durability. |

McCloskey parts help machines last longer, even in the harshest environments.

Eagle Crusher

Eagle Crusher is recognized for durability and customer support.

- They offer an UltraMax lifetime rotor warranty, unique in North America.

- Owners must provide condition reports and use Eagle-approved parts to keep the warranty.

- This warranty gives peace of mind and shows Eagle Crusher’s confidence in their products.

McLanahan

McLanahan stands out for custom-engineered solutions. They test materials in their own lab to design the right crusher parts for each job.

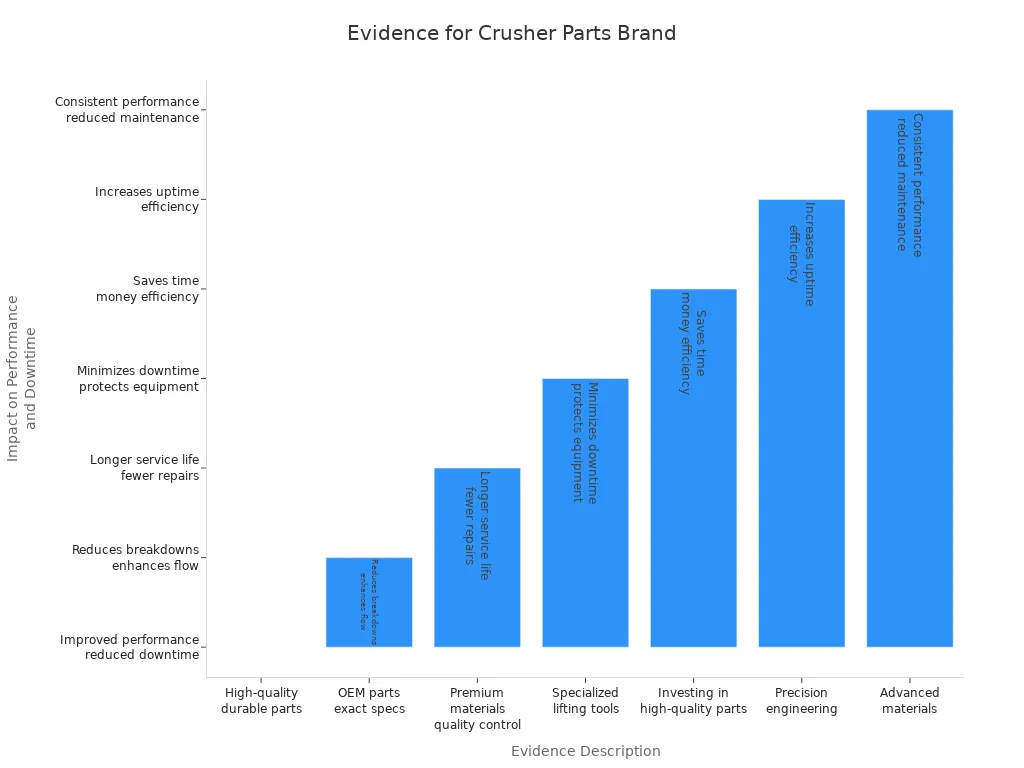

| Evidence Description | Supporting Factor |

|---|---|

| Custom engineering based on material testing | Custom-engineered solutions |

| Carbide impregnated weld-on teeth for longer wear life | High-quality wear parts |

| Reduced maintenance leads to longer plant operation | Focus on efficiency and durability |

McLanahan’s focus on efficiency and durability helps customers save time and money.

ZENITH

ZENITH offers a wide range of crusher parts at competitive prices.

Here’s a quick look at their price range:

| Crusher Type | Price Range |

|---|---|

| Jaw Crusher | $30,000 – $500,000+ |

| Gyratory Crusher | $300,000 – $2,000,000+ |

| Cone Crusher | $150,000 – $1,000,000+ |

| Impact Crusher | $50,000 – $800,000+ |

| Sand Making Machine | $80,000 – $500,000+ |

ZENITH helps customers find the right part for their budget and needs.

Kleemann

Kleemann focuses on sustainability and efficiency.

| Feature | Description |

|---|---|

| Efficient Drive | Direct drive with high fuel efficiency reduces emissions. |

| All-electric Components | Electric conveying components minimize environmental impact. |

| Noise Protection | Optional package reduces noise pollution. |

| Dust Reduction | Water nozzles reduce dust emissions. |

Kleemann’s mobile plants recycle up to 90% of mineral building waste. Their all-electric drive concept allows for zero emissions and low power use per ton of product.

Columbia Steel

Columbia Steel has over a century of experience in crusher parts. Customers often report improved output and longer wear life.

| Feedback Point | Description |

|---|---|

| Improved Crusher Output | New cone mantle design increases output. |

| Unique Mantle Modification | Directs feed more efficiently into the crushing chamber. |

| Increased Wear Life | Wear life increases by 50% to 300%, depending on the application. |

Columbia Steel uses proprietary alloys for extra wear and heat resistance.

AIMIX

AIMIX stands out for strong after-sales support and customer service.

| Feature | Description |

|---|---|

| Technical Assistance | Remote troubleshooting and on-site help for complex issues. |

| Spare Parts Provision | Steady supply of critical components to minimize downtime. |

| Regular Inspections | Trained technicians assess and recommend maintenance. |

| Repair and Refurbishment | Skilled technicians restore equipment to optimal condition. |

| Equipment Operation Training | Training on machine controls, safety, and troubleshooting. |

| Maintenance Training | Hands-on workshops for preventive maintenance and inspection. |

AIMIX helps customers keep their crusher parts working at their best.

Why These Crusher Parts Brands Are Trusted

Product Quality and Durability

Top brands focus on making Crusher Parts that last. They use strong metals and test each part for toughness. Many companies, like Metso and Columbia Steel, design parts to handle heavy loads and rough materials. Operators notice fewer breakdowns and longer machine life. This means less time fixing equipment and more time working.

Customer Service and Support

Great customer service sets these brands apart. Companies like AIMIX and Eagle Crusher offer fast help when problems come up. They provide spare parts quickly and send experts to solve tough issues. Many brands also give training for safe and easy machine use. Good support helps customers keep their machines running smoothly.

Industry Recognition and Certifications

Trusted brands earn important certifications. These show that their Crusher Parts meet high standards. For example:

| Brand | Certifications |

|---|---|

| ISO9001 Cone Crusher | ISO9001:2000, CE, ROHS |

| Vertical Shaft Impact Stone Crusher | CE, ISO |

| CS Spring Cone Crusher | CE, ISO9001:2015 |

These certifications prove that the brands care about safety and quality.

Innovation and Technology

Leading brands use new technology to improve performance. Some brands add real-time monitoring and automatic controls. Others use AI to watch the machines and make changes for better results. Here are some recent advancements:

- Real-time monitoring and optimization of the crushing process.

- Track-mounted equipment for better movement in tight spaces.

- Hybrid and electric drives to lower emissions and save energy.

- Fully automated screening systems with remote monitoring.

These features help customers get more from their Crusher Parts and work more efficiently.

Crusher Parts Brand Comparison Table

Product Quality

Top brands focus on making strong and reliable parts. Metso and Sandvik use special metals that last longer. Columbia Steel designs parts that handle tough jobs. Operators notice fewer breakdowns and better performance. Many brands test their products before shipping. This helps customers trust the quality.

Price Range

Prices can change based on the brand and type of part. ZENITH offers a wide range, from budget-friendly to premium. Some brands, like Terex and Kleemann, cost more because they use advanced technology. Customers often pay more for parts that last longer. A higher price sometimes means better value over time.

Availability

Most leading brands have a global network. Sandvik and Astec Industries make it easy to find parts in many countries. JXSC offers 24/7 support and a worldwide network. Quick delivery helps reduce downtime. Customers like brands that keep parts in stock and ship fast.

Warranty and After-Sales Service

Warranty and support matter a lot. Komatsu gives a 24-month or 4,000-hour warranty. They also offer strong support for their products. JXSC does not list a set warranty, but they provide 24/7 help and quick responses. Many brands send experts to help with repairs or training. Good after-sales service keeps machines running longer.

| Brand | Warranty Duration | After-Sales Service Options |

|---|---|---|

| Komatsu | 24 months or 4,000 hours | Trust in product durability; strong support |

| JXSC | N/A | 24/7 support, quick response, worldwide network |

Tip: Always check the warranty and support before buying Crusher Parts. This can save time and money later.

How to Choose the Right Crusher Parts Brand

Assessing Your Application Needs

Every job site has different needs. Operators should look at several factors before picking a brand.

- Abrasiveness and hardness of the material

- Maximum size the crusher can handle

- Desired grain size after crushing

- Processing capacity needed

- Type of rock or material

- Production goals for each day or week

Understanding these points helps match the right Crusher Parts to the job. Comparing specifications and researching brands also makes a big difference.

Considering Budget and Total Cost of Ownership

Price matters, but it is not the only thing to watch. The total cost of ownership includes more than just the purchase price.

| Factor | Impact on TCO |

|---|---|

| Material Quality | Better materials last longer and save money over time. |

| Construction | Stronger build means fewer repairs and less downtime. |

Established brands may cost more, but they often offer better reliability and support. Choosing the right parts can boost productivity and lower repair costs.

Evaluating Support and Service Options

Optimized maintenance is a key competitive advantage for an aggregate producer. Dealing with multiple service providers and brands can become a significant risk as response times, quality and inventories vary across suppliers. For crushers, it’s the spare parts that ensure operational uptime; they enable the crusher and the process to keep on going.

A strong warranty and fast support help keep machines running. Centralized service makes maintenance easier and improves uptime.

Checking for Local Availability

Quick access to parts keeps projects on track. Buyers should check shipping times and local stock. Domestic brands often ship faster, sometimes in about 20 days. Brands like Sandvik, Terex, and Metso Outotec have global networks, making it easier to find parts and support nearby.

Metso, Sandvik, Terex, and other trusted brands lead the way in 2025. Each brand offers unique strengths. Operators should match these strengths to their own needs.

- Review the comparison table

- Think about support and price

Smart choices keep crushers running longer and save money.

FAQ

What makes a crusher part brand trustworthy?

A trustworthy brand uses strong materials, tests parts for quality, and offers good support. Many operators choose brands with a long history of reliable products.

How often should operators replace crusher parts?

Replacement depends on usage and material hardness. Most operators check parts every few months. Regular checks help prevent sudden breakdowns.

Can operators mix parts from different brands?

Mixing parts from different brands can cause fit or performance issues. Operators should check compatibility before using parts from another brand.

Post time: Sep-02-2025